Installation instructions for SPC panels without integrated underlay

1.

Before delivering the floor to the installation site, doors and windows must be installed in the building and all wet trades must be completed, e.g. plastering, construction of partition walls, painting, etc. If there are basements under the installation site in the building, they must be dry and well ventilated. SPC panels can be installed in all residential rooms such as: living rooms, bedrooms, kitchens and bathrooms and in most public facilities.

SPC floors should be used as intended for specific room types (utility class) in accordance with ISO 10874. You can find information about the intended use of a specific SPC floor for different room types (utility class) on the product package, in the product’s technical data sheet and in the product description at www.barlinek.com.

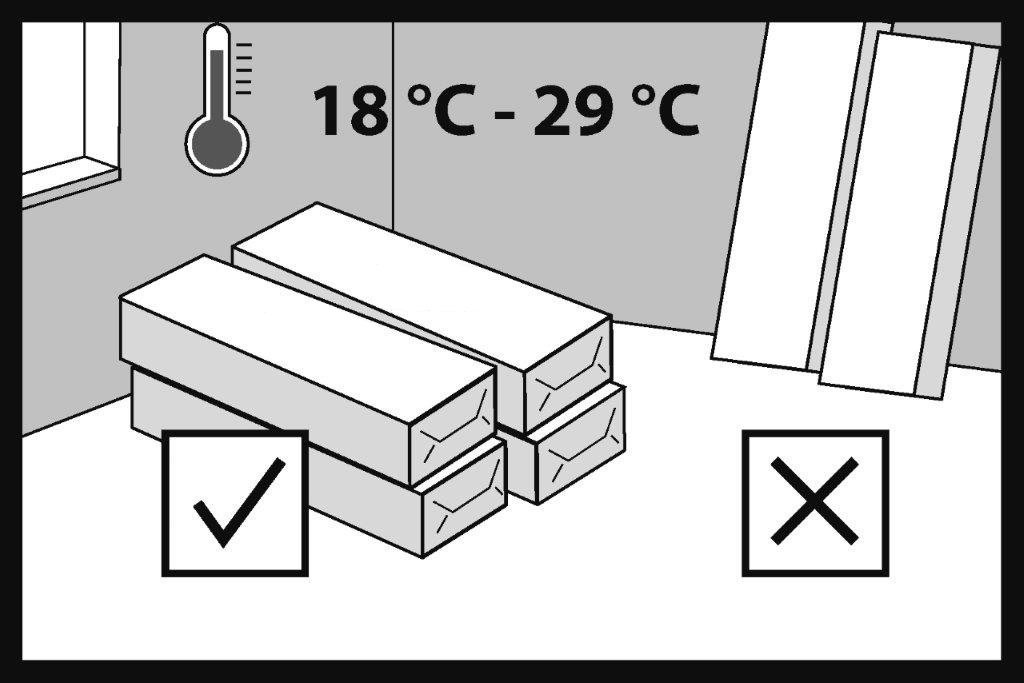

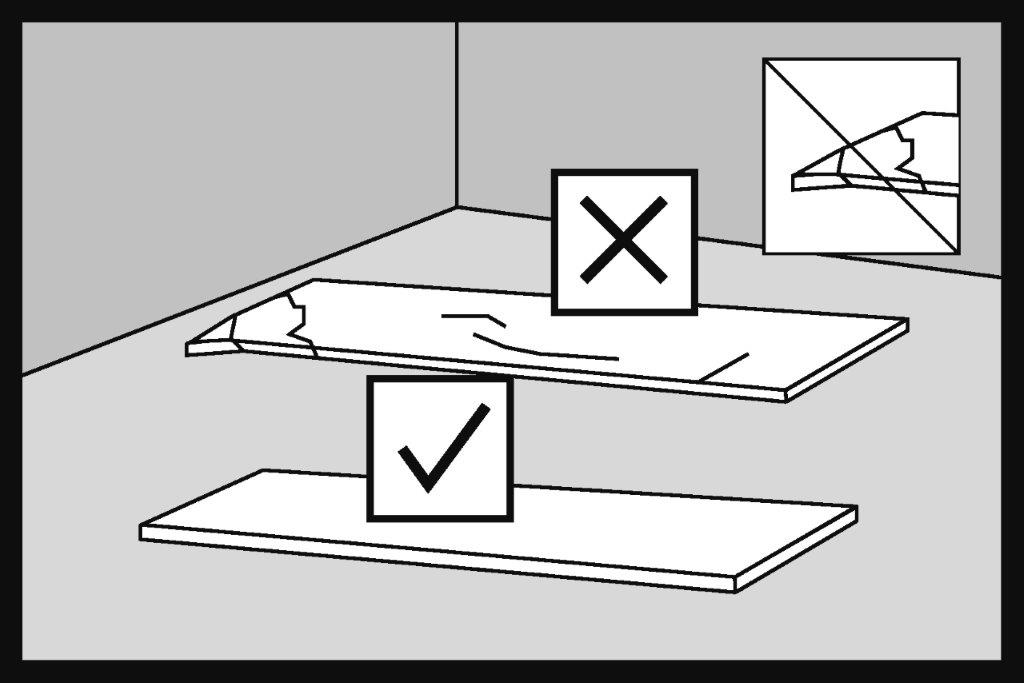

Handle packages containing SPC floor panels carefully during transport and unloading to avoid any mechanical damage. Store SPC floor panels in their original packaging in a dry place, in a horizontal position, on pallets or wooden beams. Maintain a free space of at least 75 mm between the SPC panel packaging and the substrate.

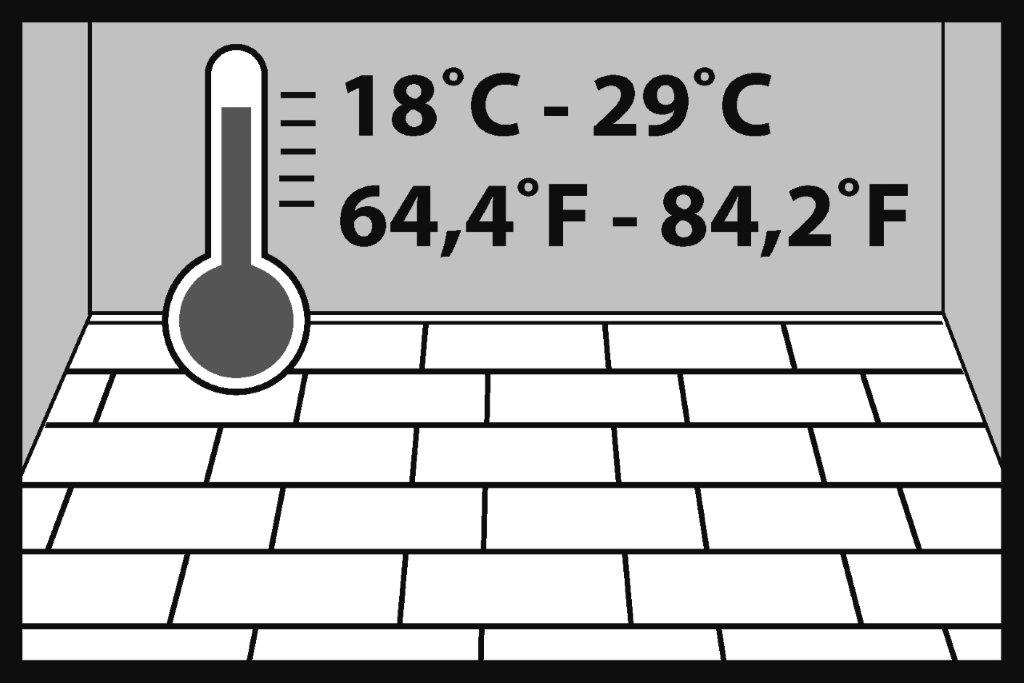

To ensure its acclimatisation, store the floor for at least 24 hours in its original packaging in the room where it is to be installed. The air temperature in the room should be between +18°C and +29°C.

2.

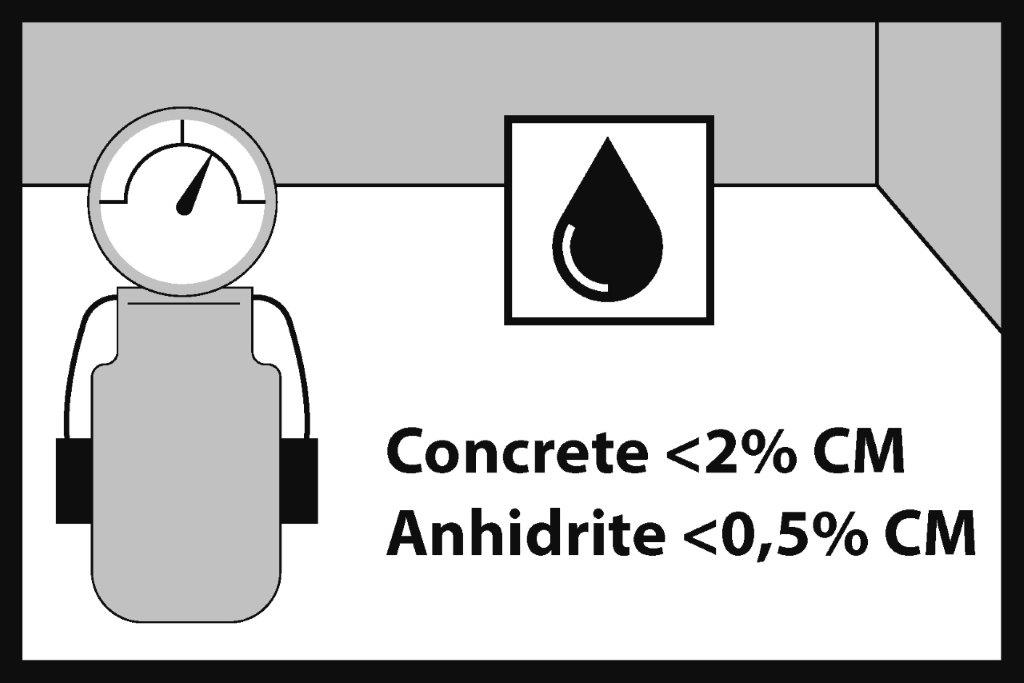

The moisture content (humidity) of the wooden subfloor (or wood-based boards) should not exceed 12%. The moisture content (humidity) should not exceed 2% for concrete subfloor and 0.5% for anhydrite subfloor. The measurement results should be documented.

3.

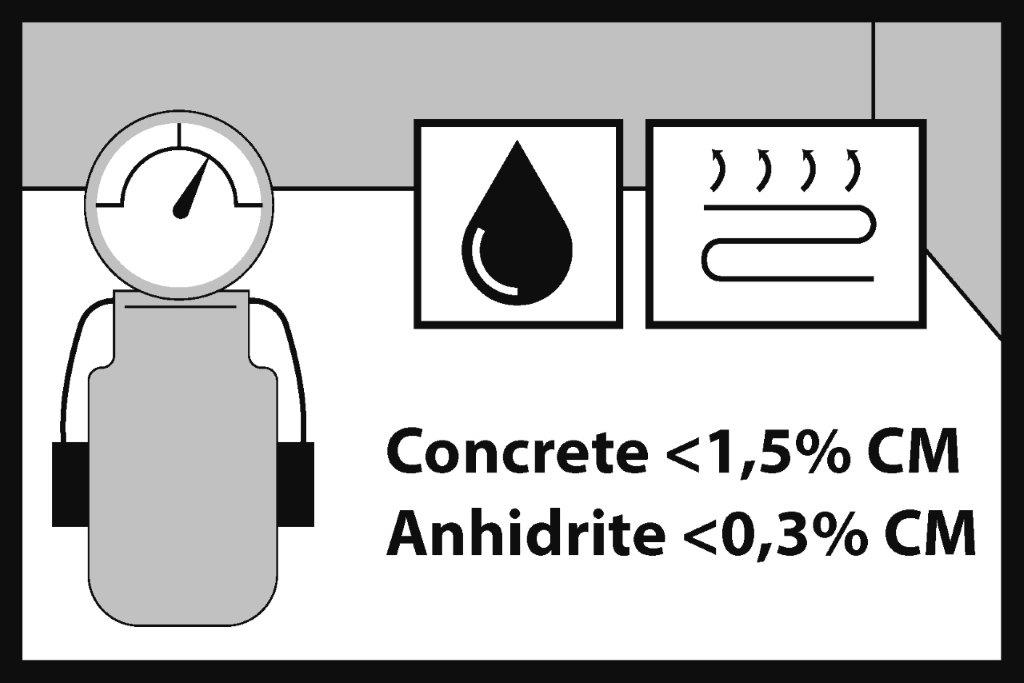

If the SPC panels are installed on an underfloor heating system, the moisture content (humidity) should not exceed 1.5% for concrete subfloor and 0.3% for anhydrite subfloor. The measurement results should be documented.

4.

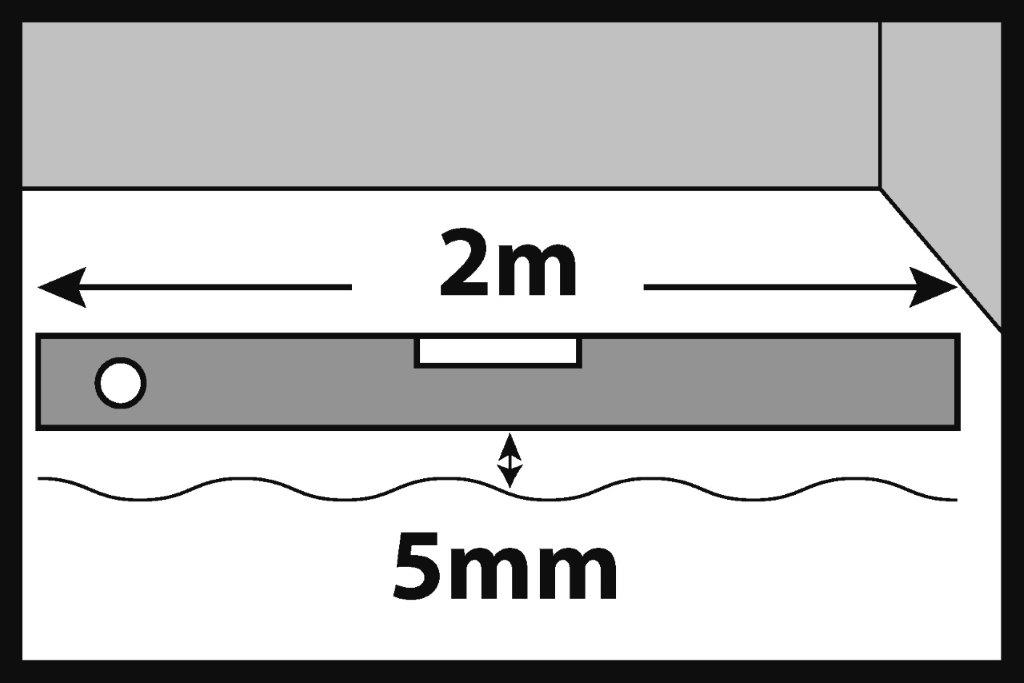

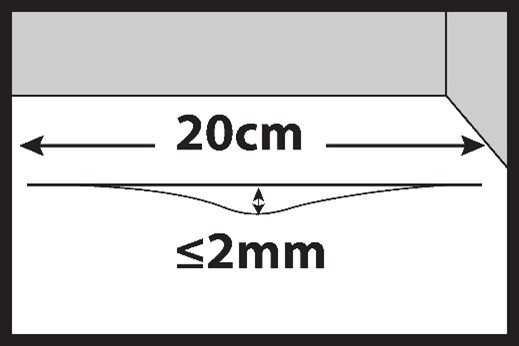

The maximum permissible unevenness is up to 5 mm, measured over a length of 2 m. Spot/local unevenness must not exceed 2 mm over a length of 20 cm.

5.

Brush or vacuum clean the subfloor before installing the SPC panels. The subfloor should be free of dust, debris, paints, varnishes, wax, grease, oil, hardeners, sealants, solvents, sand, glue residues, fats and other foreign bodies.

6.

The subfloor should be dry, stable without scratches and cracks and clean without visible dirt. Fill cracks and defects in cement or anhydrite subfloor with filler. For floating installation on ceramic tiles, fill joints with a width of more than 5 mm and a depth of 2 mm with filler. For adhesive installation, fill all joints with putty and read the adhesive system manufacturer’s guidelines.

For information on the adhesive system recommended for the installation of the SPC floors, please visit www.barlinek.com

Plywood, OSB, chipboard must be structurally solid and installed in accordance with the board manufacturer’s recommendations. We recommend installing wood-based boards in two layers, connected with wood screws. Install the boards in the first and the second layer with the staggered edges. The wood-based board substrate must provide adequate stiffness and support for the correct installation of the SPC floor. The board joints should be smooth and should not cause the boards to deflect or spring back under load.

All screw heads should be slightly recessed below the board plane.

7.

Do not install the SPC floor panels on existing soft carpet flooring, soft PVC floor lining, carpets or other similar materials.

8.

When installing the SPC panels as a floating floor, use an underlay with the following parameters:

CC – long-term static load ≥ 90 kPa

CS – short-term load ≥ 400 kPa

DL – dynamic load ≥ 4 000 000 cycles

9.

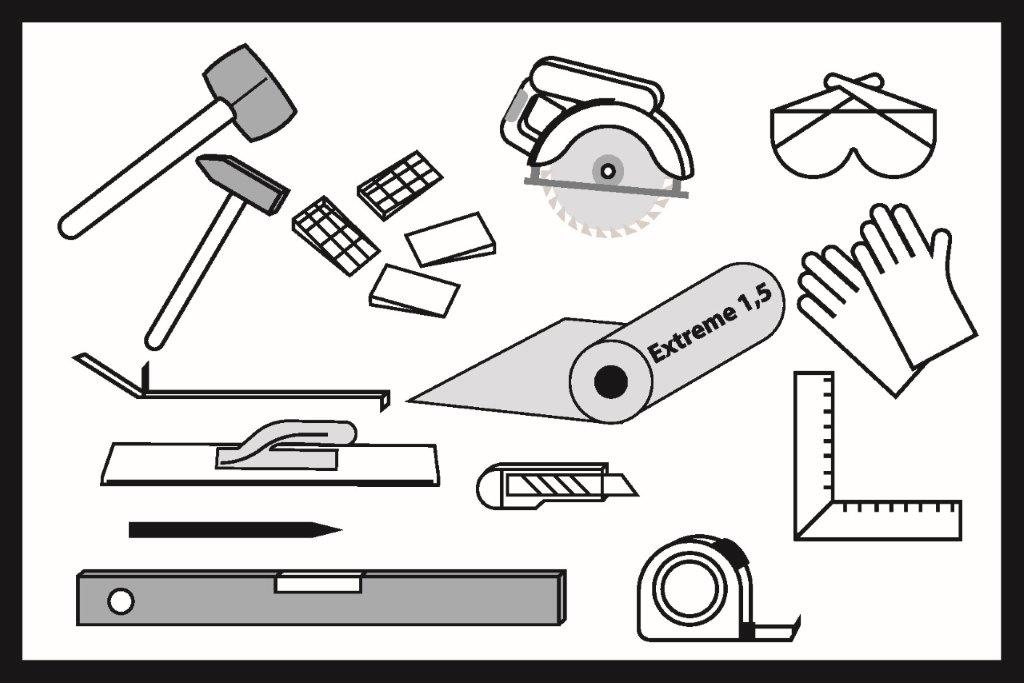

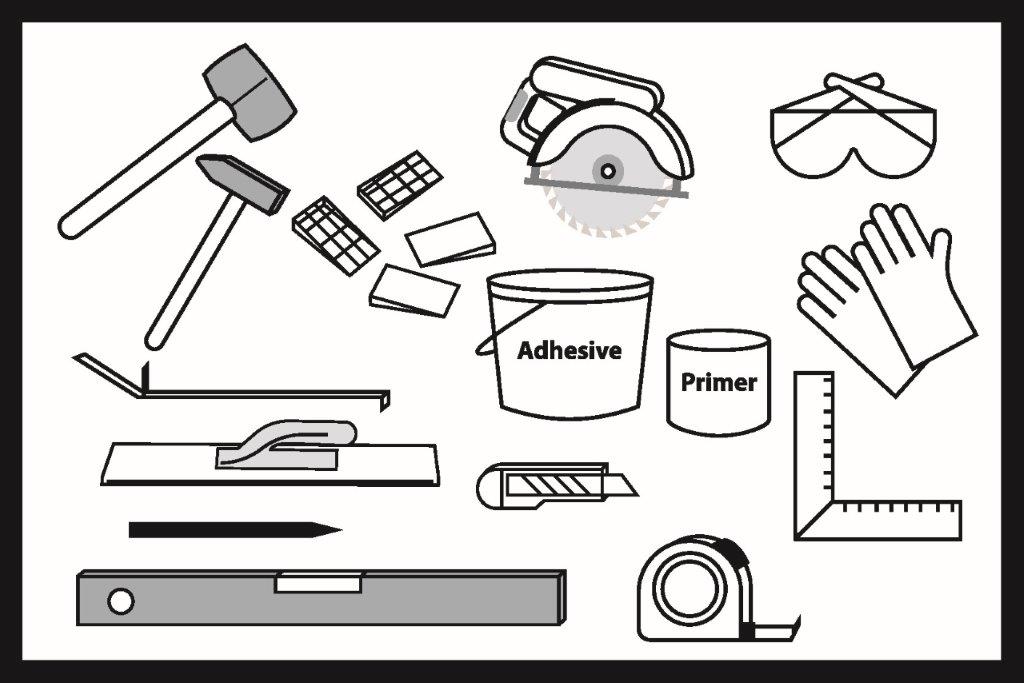

Recommended tools and materials to install the floor:

- Protective goggles

- Vacuum cleaner or sweeping brush

- Knee pads

- Protective gloves

- Non-rebounding mallet (white rubber mallet or sand filled mallet)

- Spacer wedges

- Tape measure

- Pencil

- Electric saw

- Spirit level

- Tapper

- Mounting lug

- Hammer

- A knife for cutting

- Tape for gluing the underlay

- Underlay for panels

Floor underlay is not used in the adhesive floor installation system. Use adhesive and primer. Glue the floor using the recommended adhesive system.

For more information, please visit www.barlinek.com.

10.

Before installation, the investor or fitter should check the SPC panels for compliance with the order. Check the panels for quality, finish, gloss, colour, mechanical damage (information on the product type can be found on the label or in the installation instructions or product card). In case of doubt, the investor or fitter should not use any SPC panel that they consider unsuitable for installation and should immediately contact the seller. Installing a damaged SPC panel, a panel that does not comply with the order or a panel with visible defects or unacceptable visual features will void the warranty.

11.

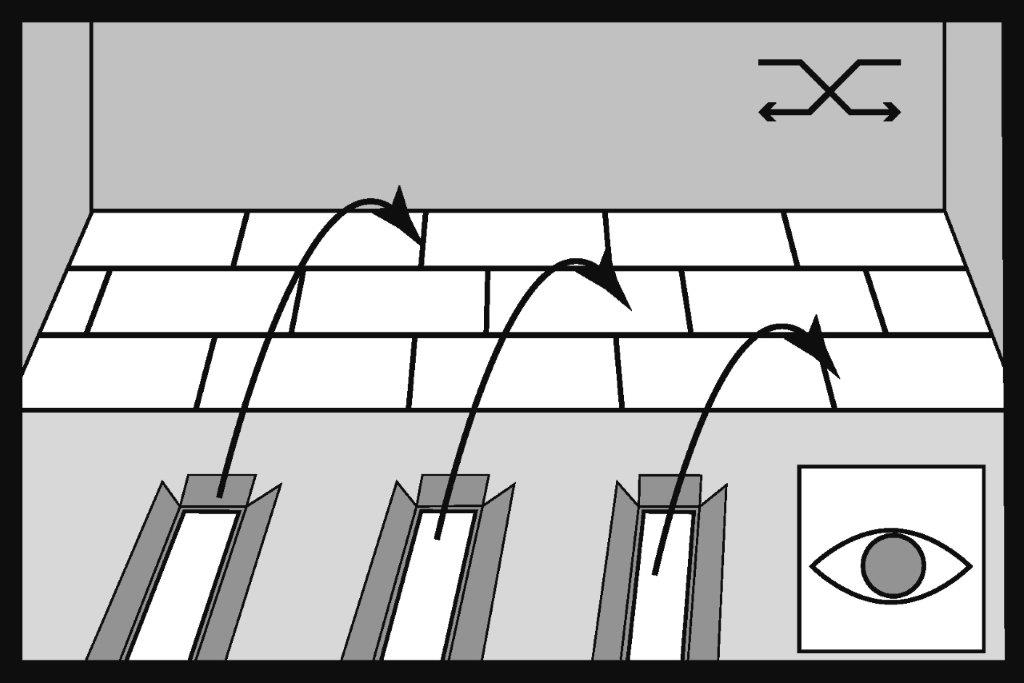

Install panels from several packages, choosing them appropriately according to colours to achieve a balanced visual effect for the floor.

Order approx. 3% more panels than the measured floor area. For rooms with many angles or obstacles and rooms where SPC panels are installed diagonally across the room or at connections with ceramic tiles, it may be necessary to order approx. 10% more panels than the measured floor area.

12.

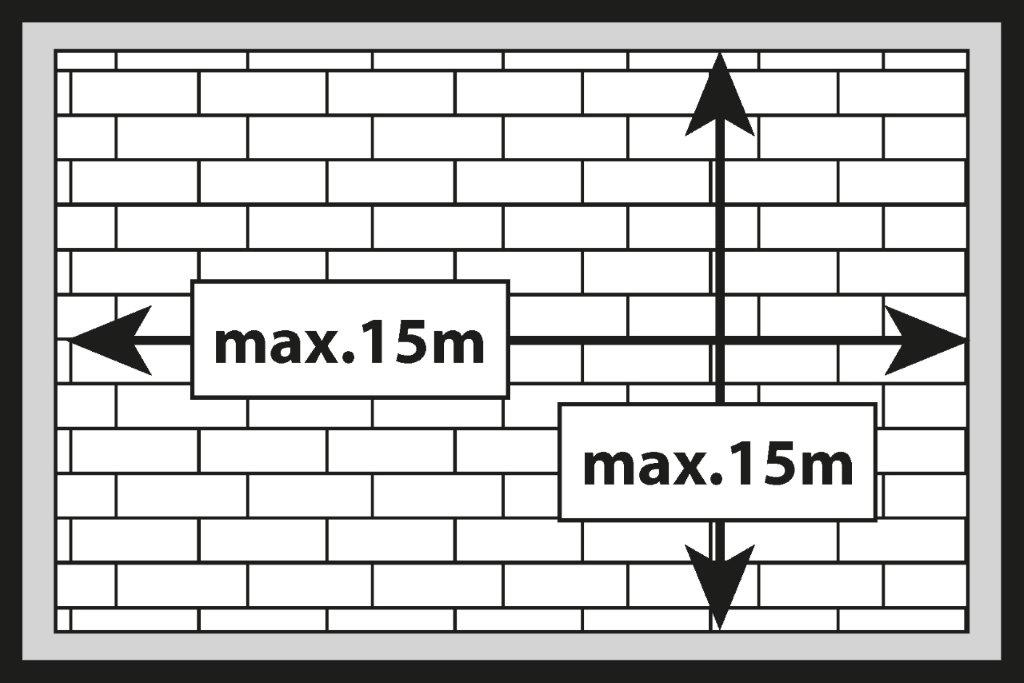

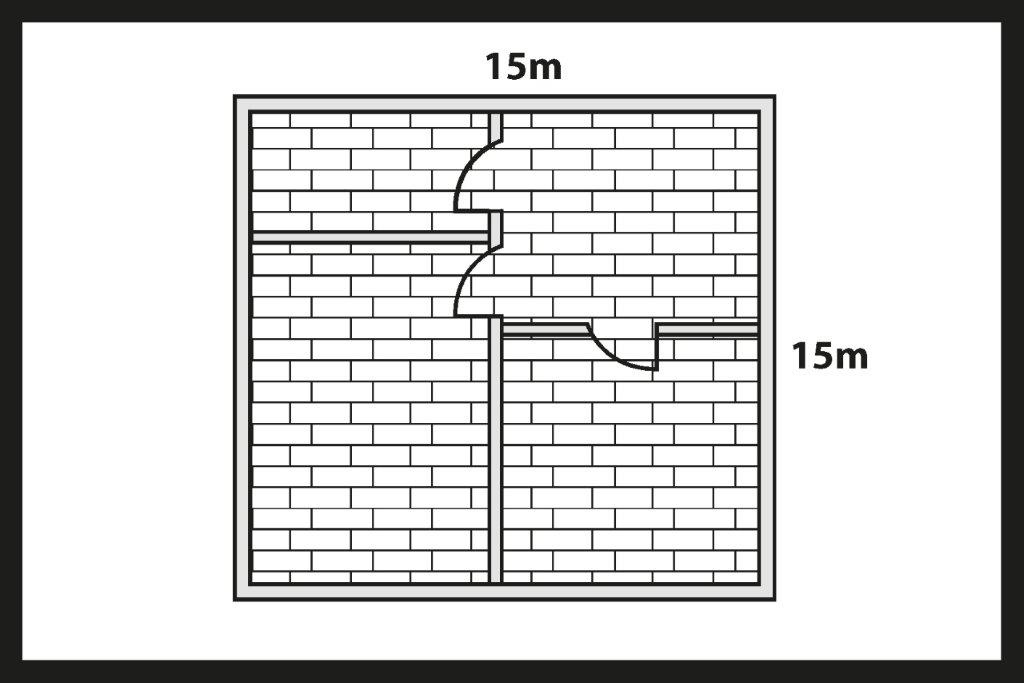

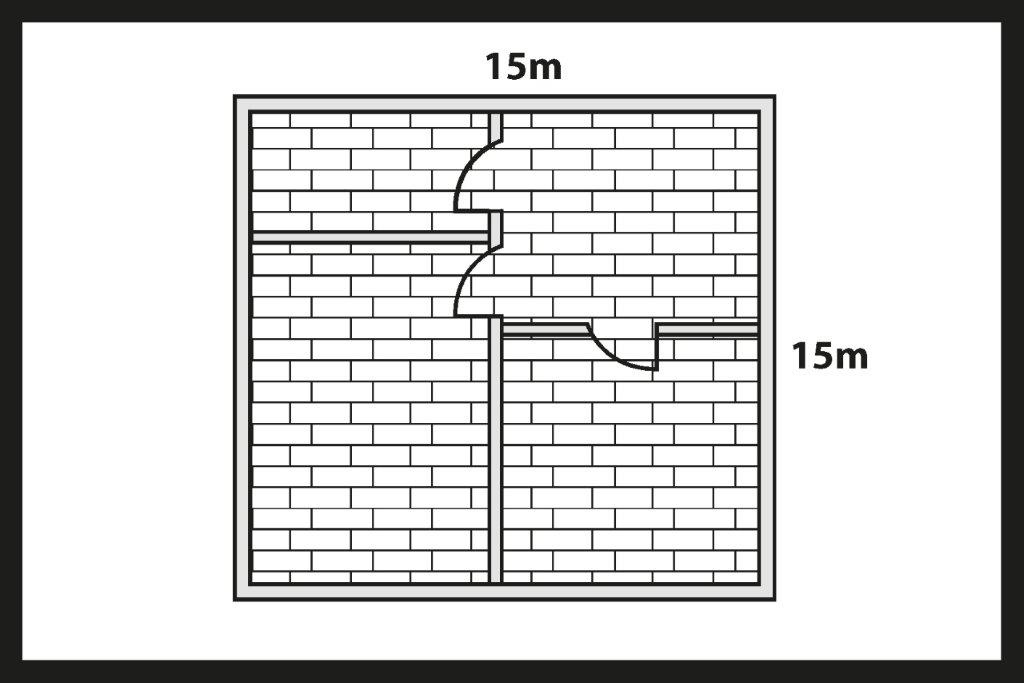

The maximum dimensions of the floor plan of a house/apartment for which the SPC floor installed as a floating floor does not require expansion gaps in doorways are 15m×15 m. For dimensions up to 15m x 15m do not make expansion gaps in doors and doorways to adjacent rooms. Make expansion gaps around walls and building elements such as stairs and columns.

13.

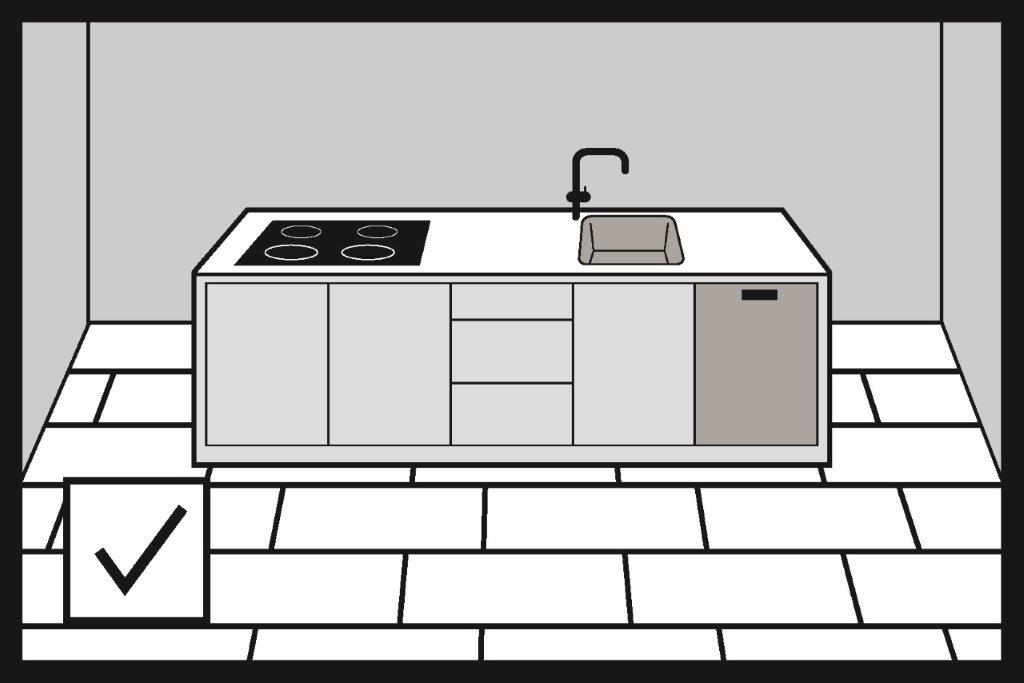

Heavy items such as a kitchen island or furniture can be placed on the floor glued to the screed or installed as a floating floor without the need to leave expansion gaps around the structure.

However, it is required to make a perimeter expansion gap around fixed elements leading from the floor to the kitchen island, e.g. water and sewage system.

Always leave expansion gaps by the walls regardless of the panel installation system.

14.

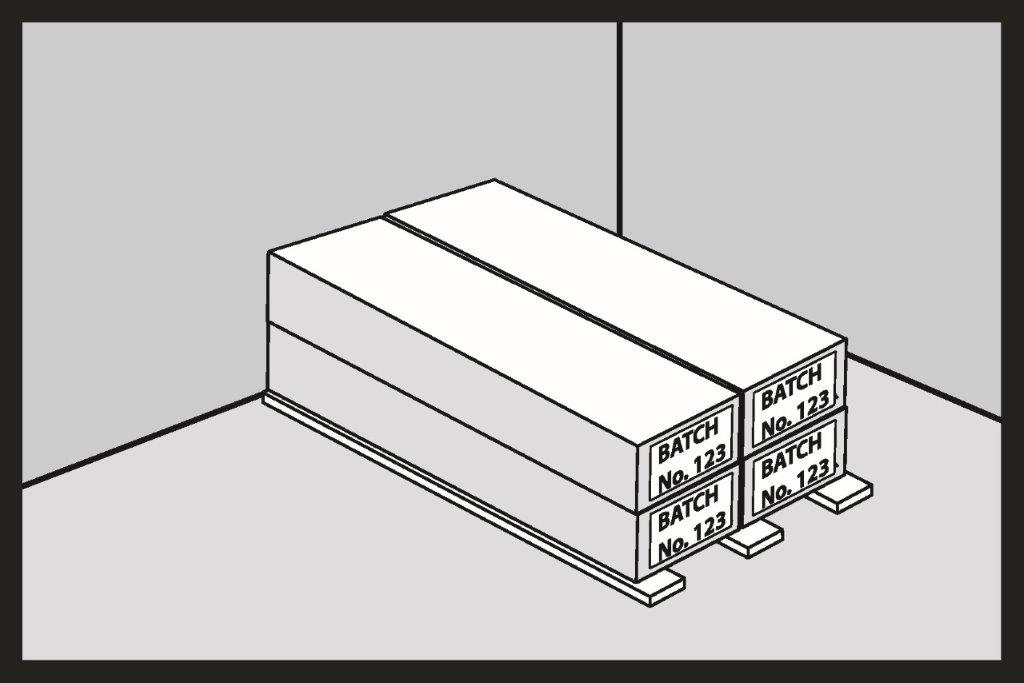

Please note that individual production batches of the SPC floors may slightly differ in shades. Therefore, floors from one production batch should be installed within one room. Check the conformity of the production batch before starting the installation. The production batch number can be found on the panel packaging (i.e. “Batch no”). To facilitate the identification of the installed floors’ production batch in the after-sales processes, make and keep a photo of the package of the installed SPC panels, with the production batch number visible.

Installation of the SPC panels as a floating floor

15.

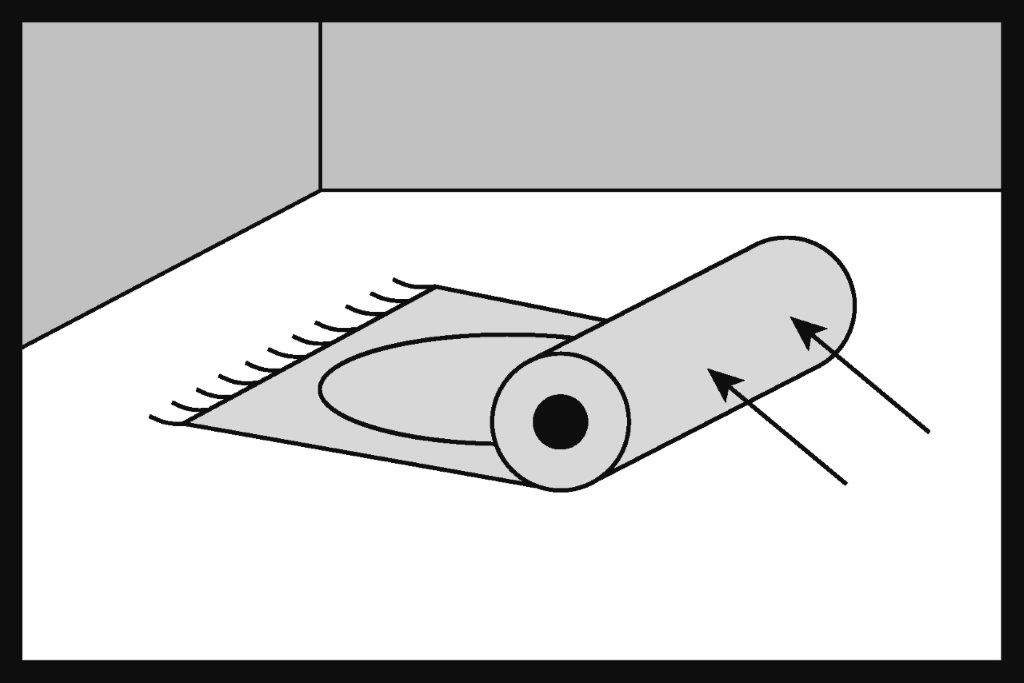

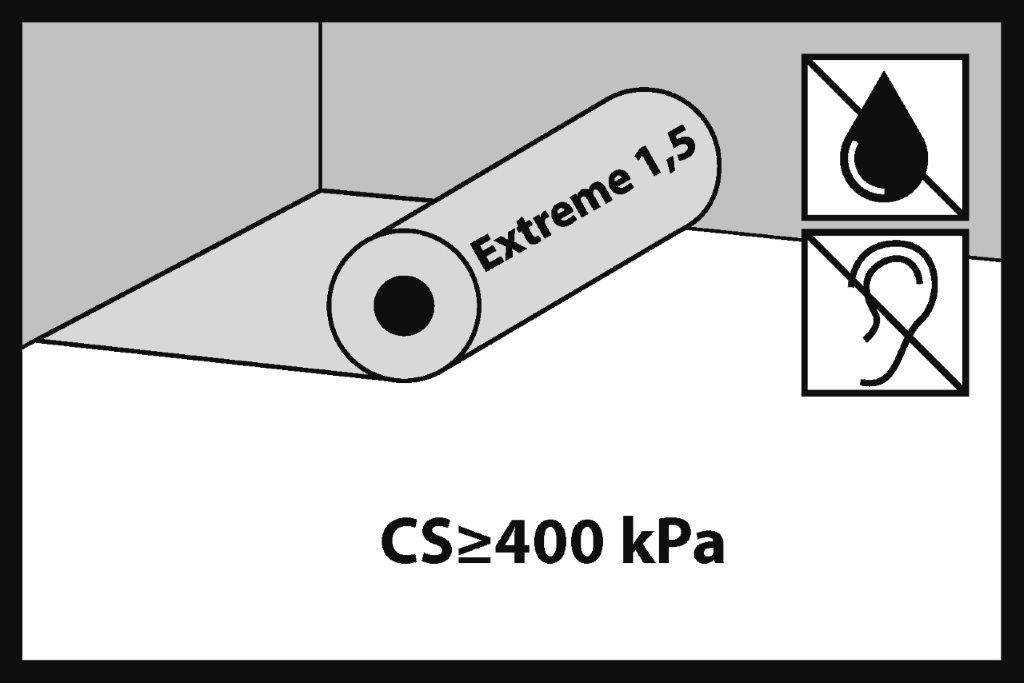

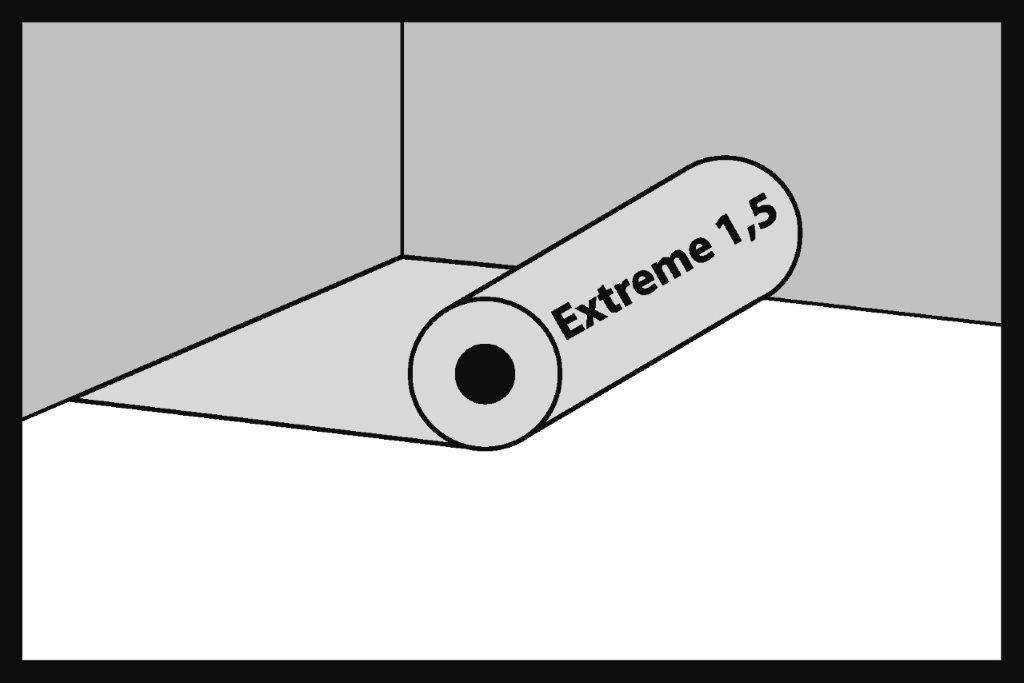

Unfold the underlay for panels. Install adjacent strips of underlay so that they touch each other. For floating installation, use an underlay with the following parameters:

CC – long-term static load ≥ 90 kPa

CS – short-term load ≥ 400 kPa

DL – dynamic load ≥ 4 000 000 cycles

The underlay must withstand various loads over its service life. Using an underlay with lower parameters results in incorrect installation of the floor and loss of warranty. Barlinek offers a dedicated Extreme 1.5 underlay that meets the indicated technical requirements.

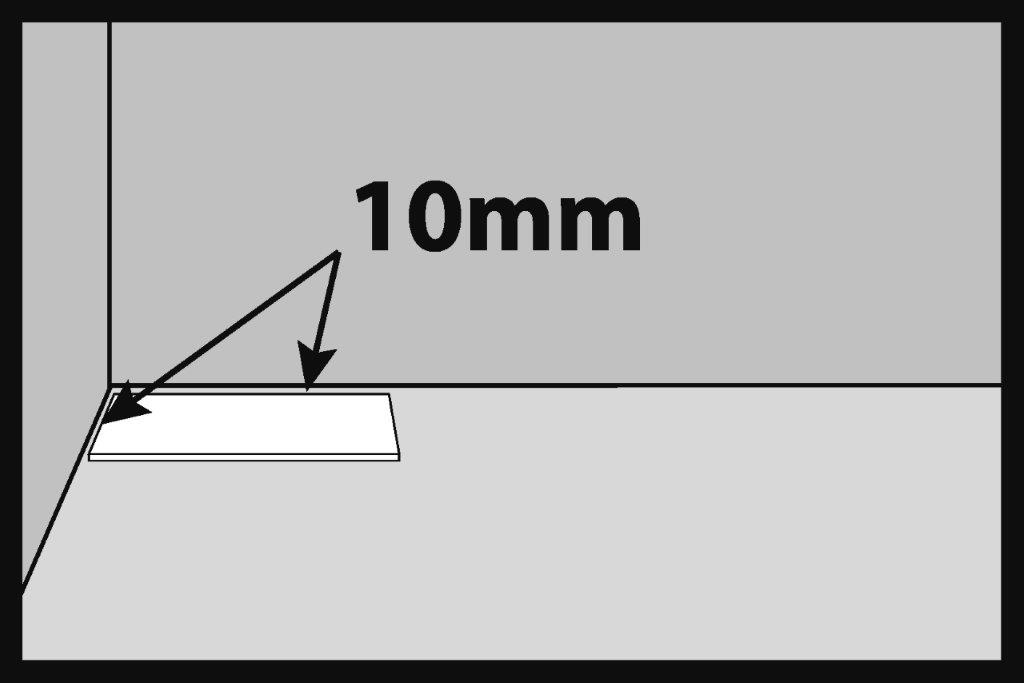

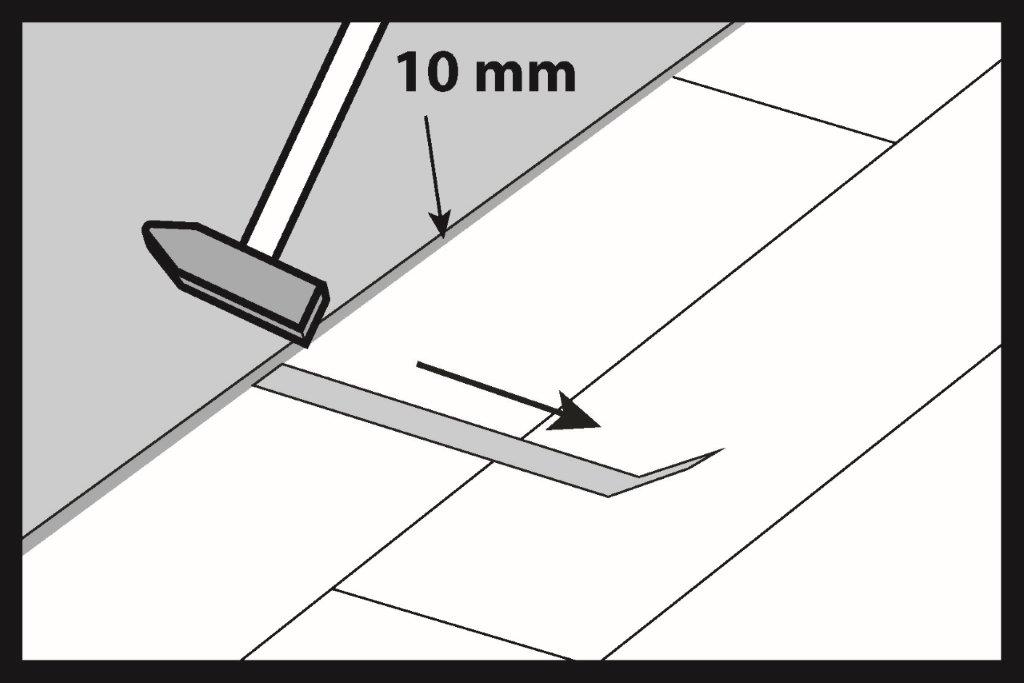

16.

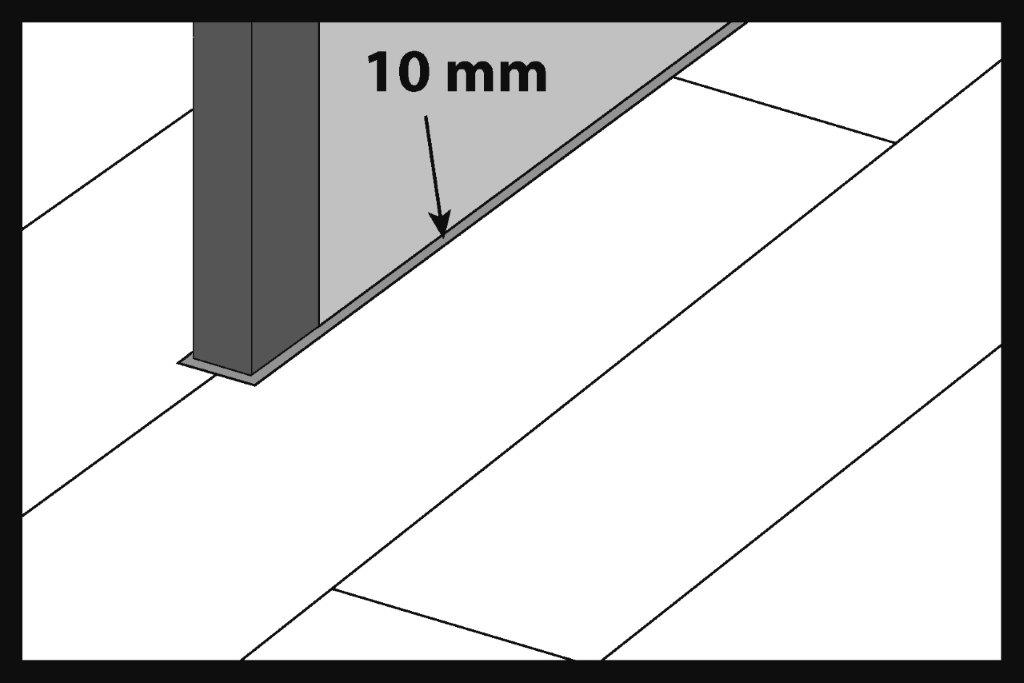

Start installing panels from the left side of the wall and continue to the right side. The width of the expansion gap should be at least 10 mm. Spacer wedges help maintain the same expansion gap width. Make the expansion gap along the perimeter of the room and around any other obstacles such as columns, stairs, ceramic tiles, etc.

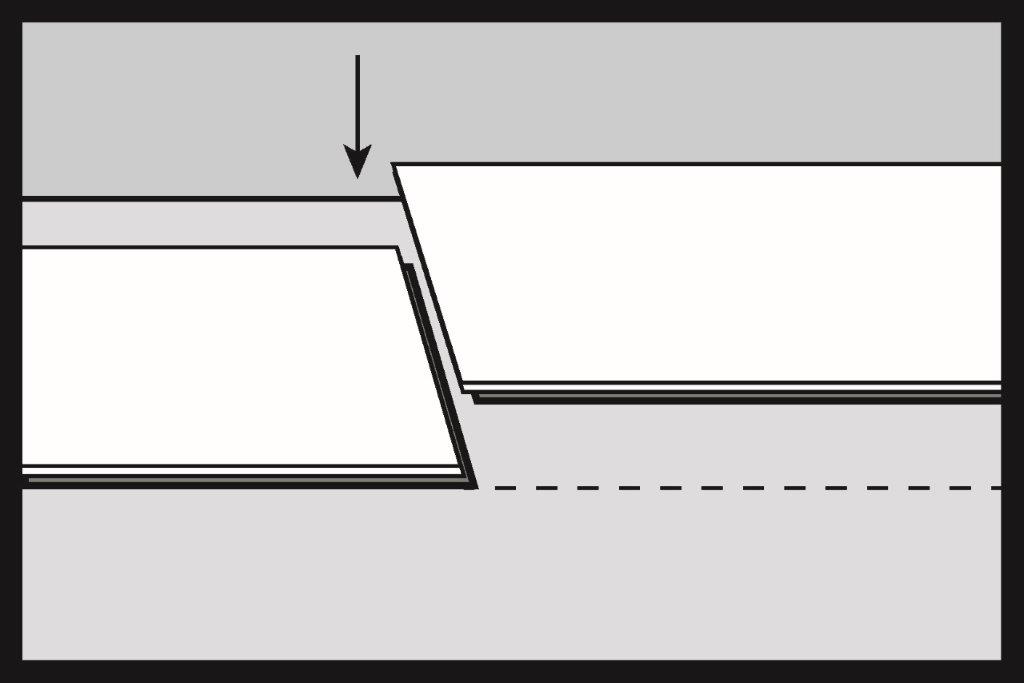

17.

Align the short edge of the next SPC panel with the edge of the preceding panel. Ensure the edges of the SPC panels align perfectly. The connected panels must be precisely aligned.

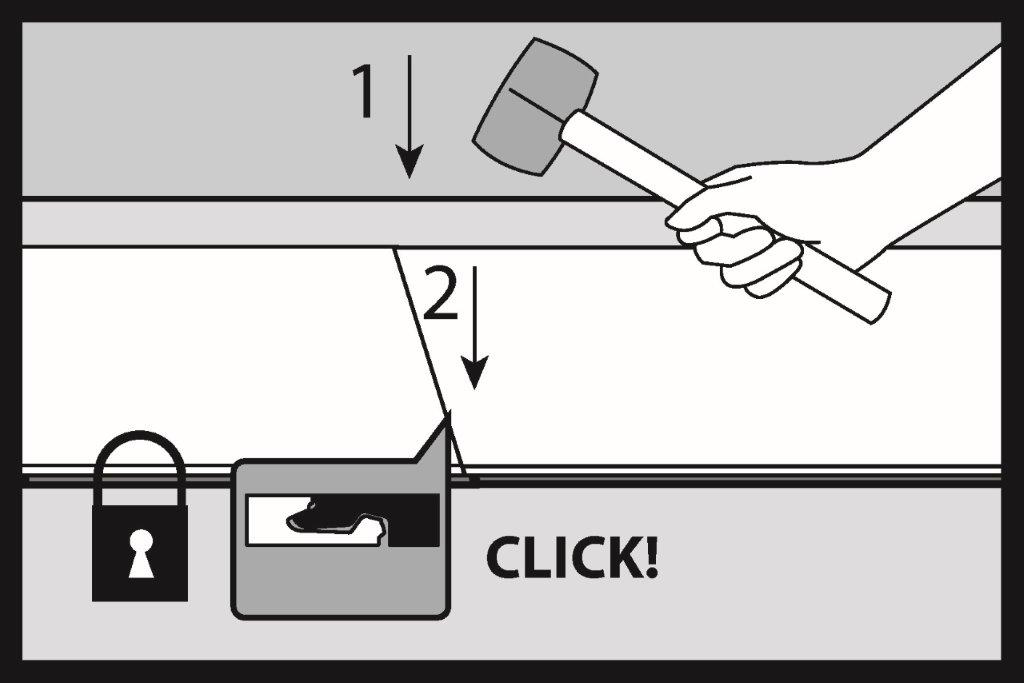

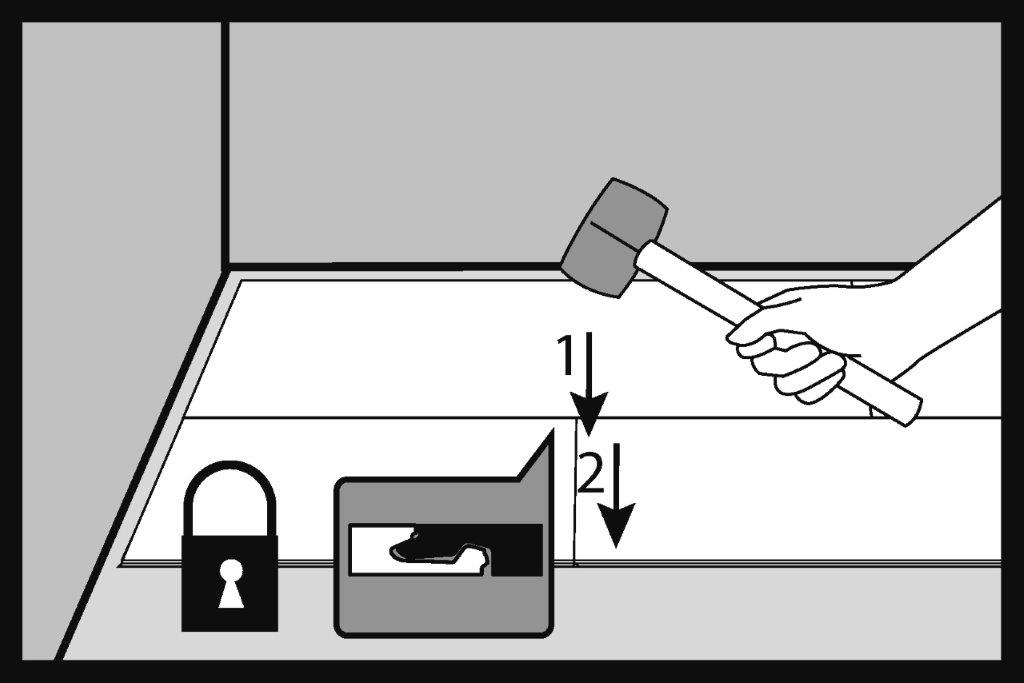

18.

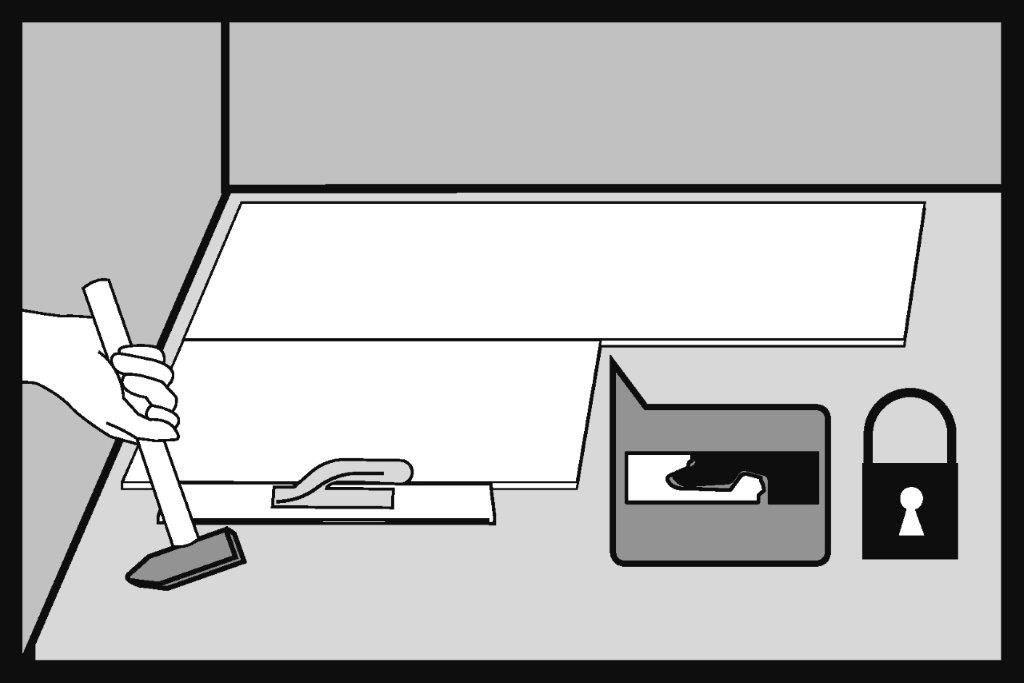

Gently tap the joint with a non-rebounding mallet (sand filled mallet or white rubber mallet) and lock the joint by tapping in sequence 1 and 2. If the joint is properly locked, the top layer of the panels should form one plane and there should be no visible difference in levels between the connected elements.

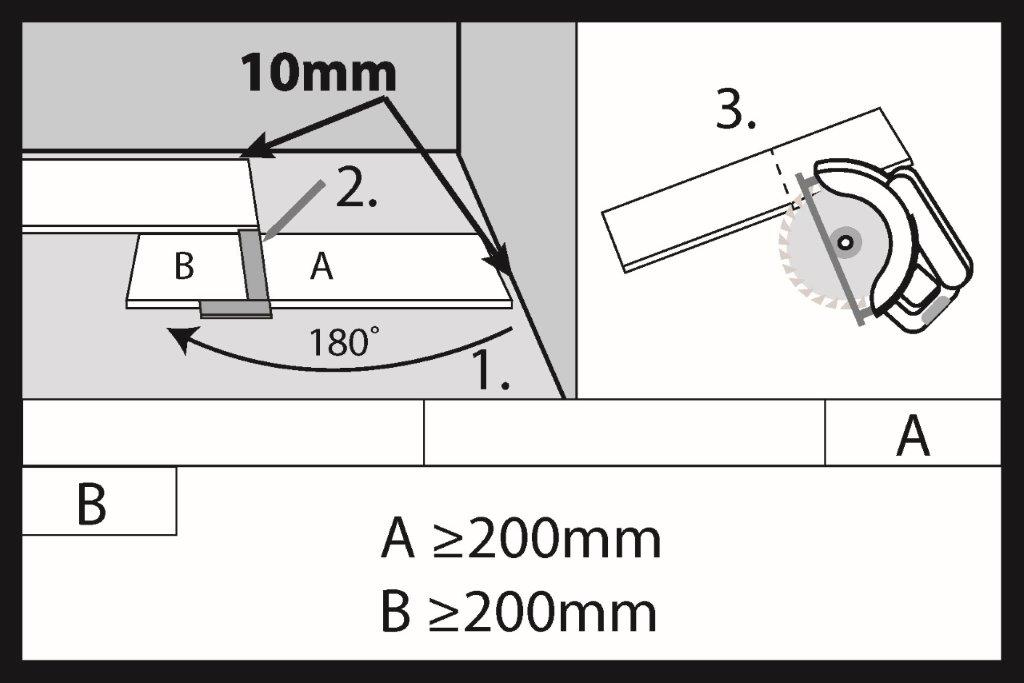

19.

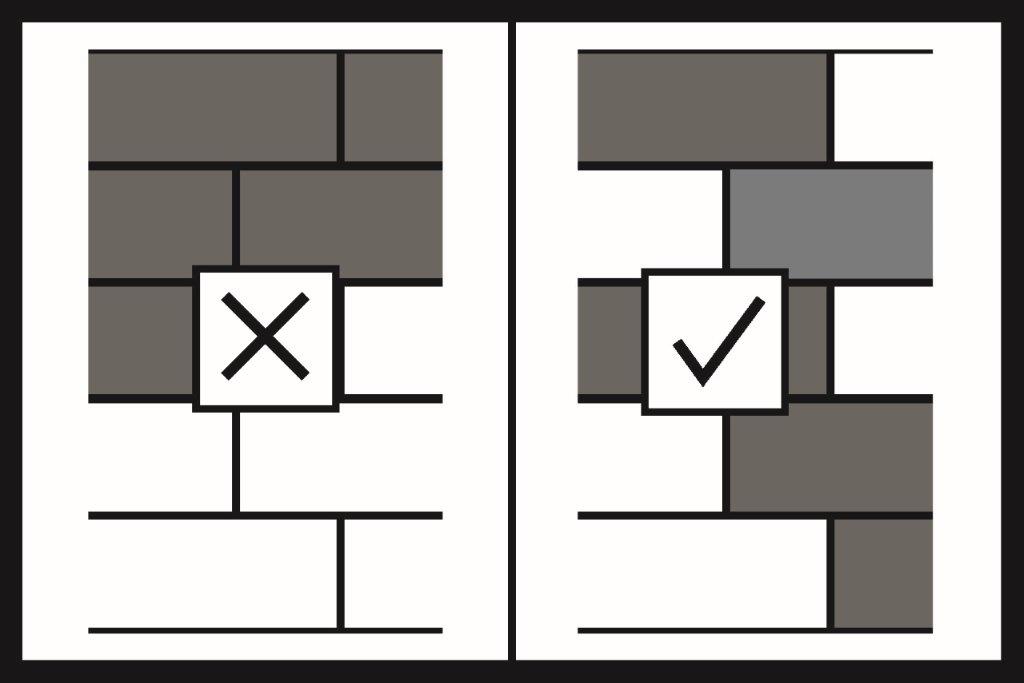

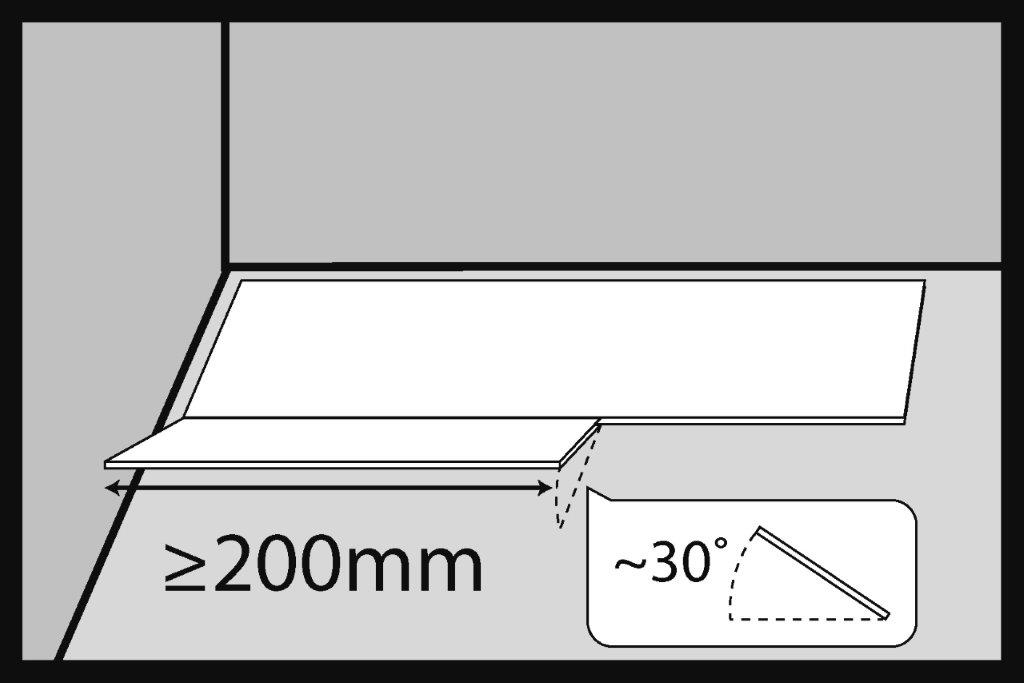

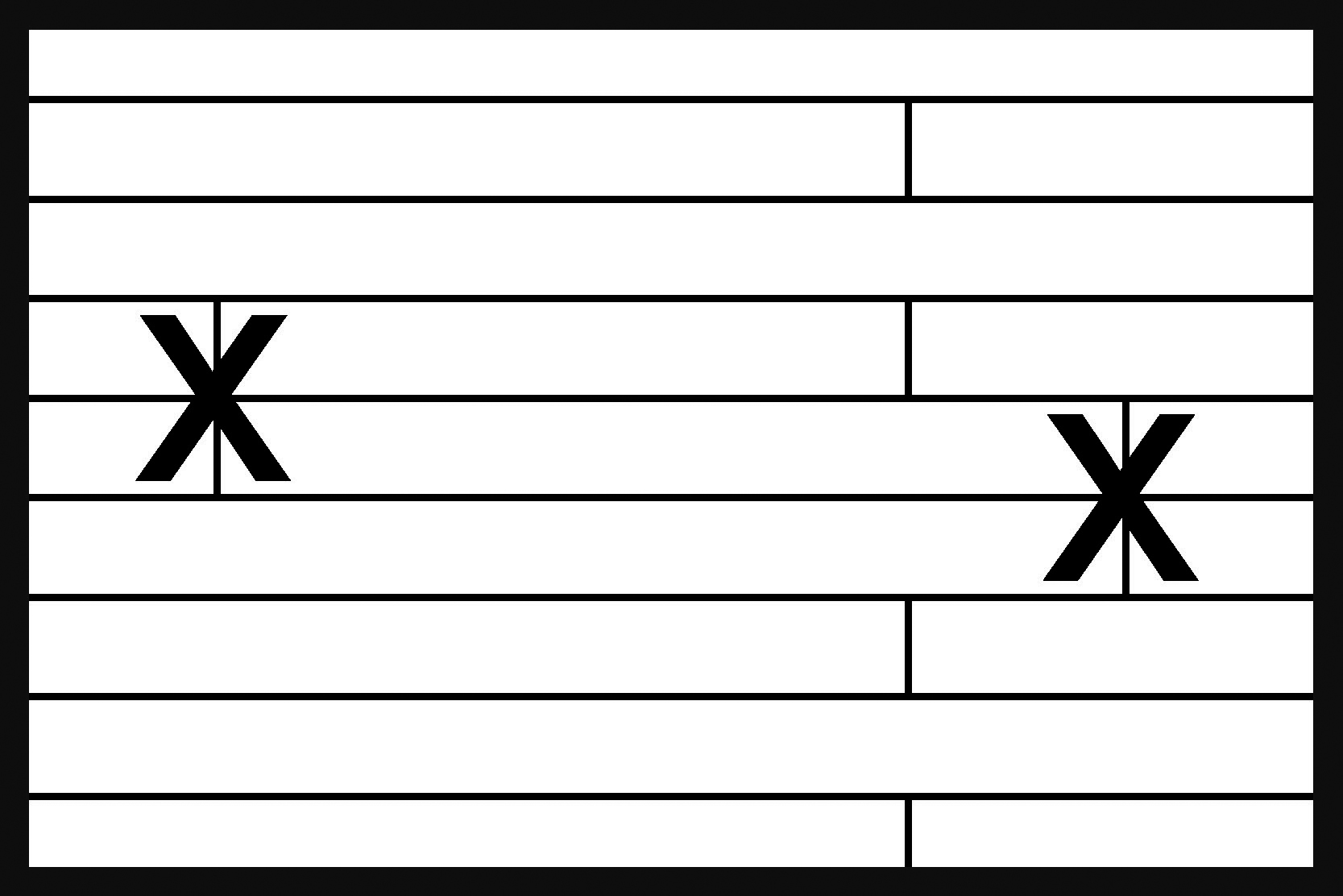

Use a hand saw or electric saw to cut the panels. When cutting the peripheral panels, remember to leave an expansion gap of at least 10 mm. The recommended length of the peripheral panel (A) in the first row of panels should be at least 200 mm. If the cut length of panel (B) is longer than 200 mm, you can use it to start laying the second row of panels. The distance between end-to-end joints in two adjacent rows of panels should be at least 200 mm.

20.

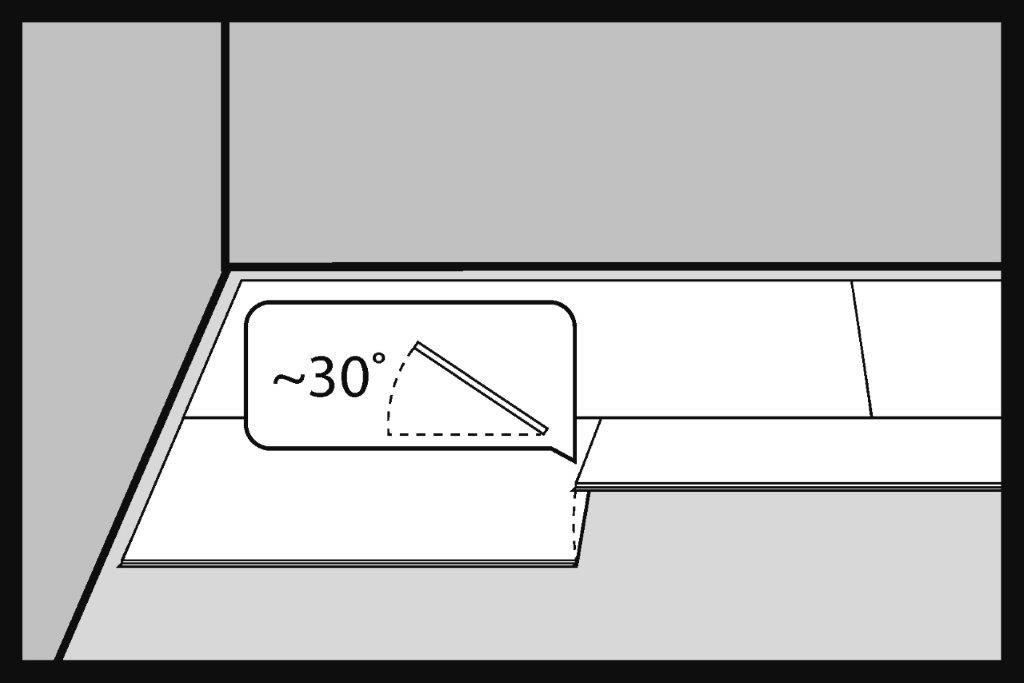

Insert the first SPC panel in the second row of panels at an angle of approximately 30° into the joint of the panel in the first row of panels. The recommended length of the installed SPC panel is minimum 200 mm.

21.

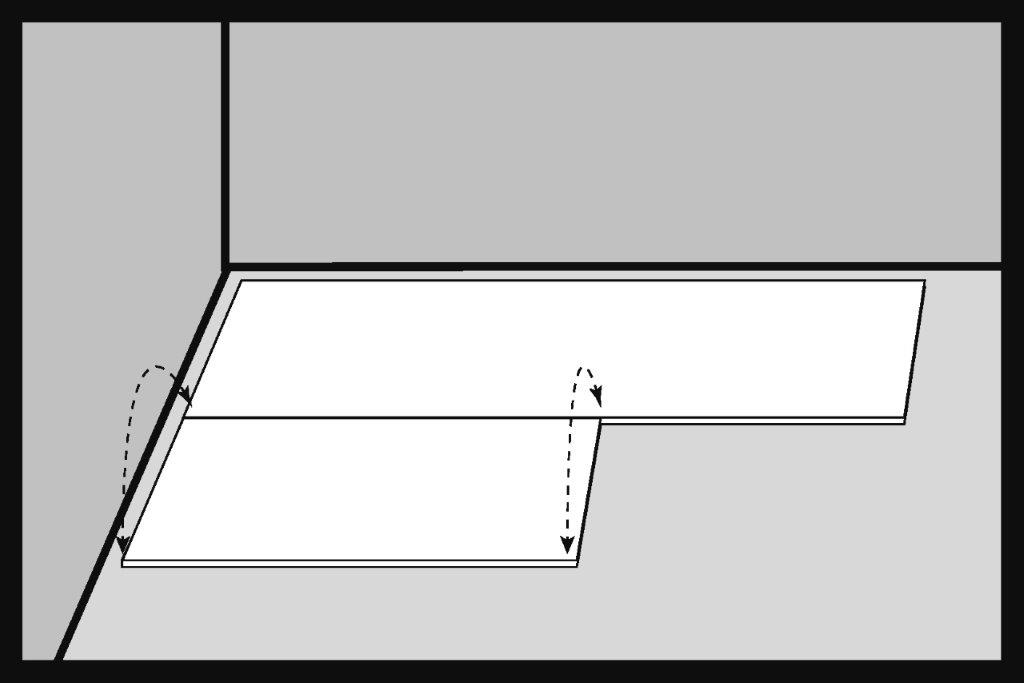

If the panel does not fall freely during installation, attempt to wiggle it in by tilting it up and pressing it down lightly.

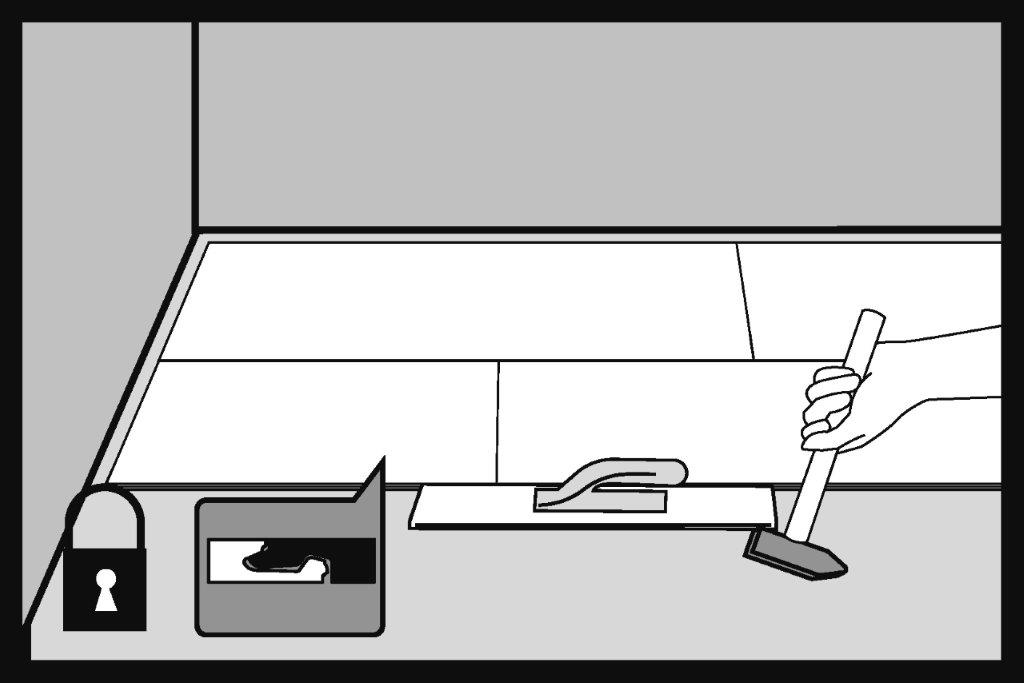

22.

Use the tapping block to tap the long side of the panel. When installing the panels, always tap the joints on the long side of the panel.

23.

Insert the second panel in the second row of panels at an angle of approximately 30° into the joint of the panel installed in the first row of panels.

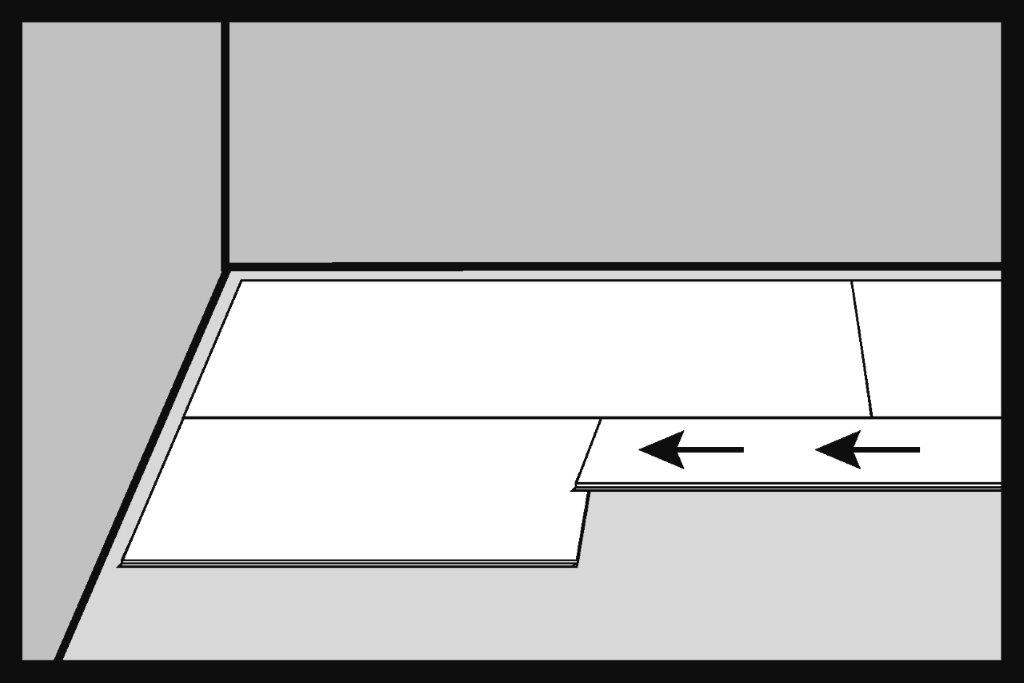

24.

Push the panels together so that their short edges touch.

25.

After lowering the panel, tap the panels together at the short sides and lock the joint by tapping in sequence 1 and 2.

26.

Use the tapping block to tap the long side of the panel. When installing the panels, always tap the joints on the long side of the panel.

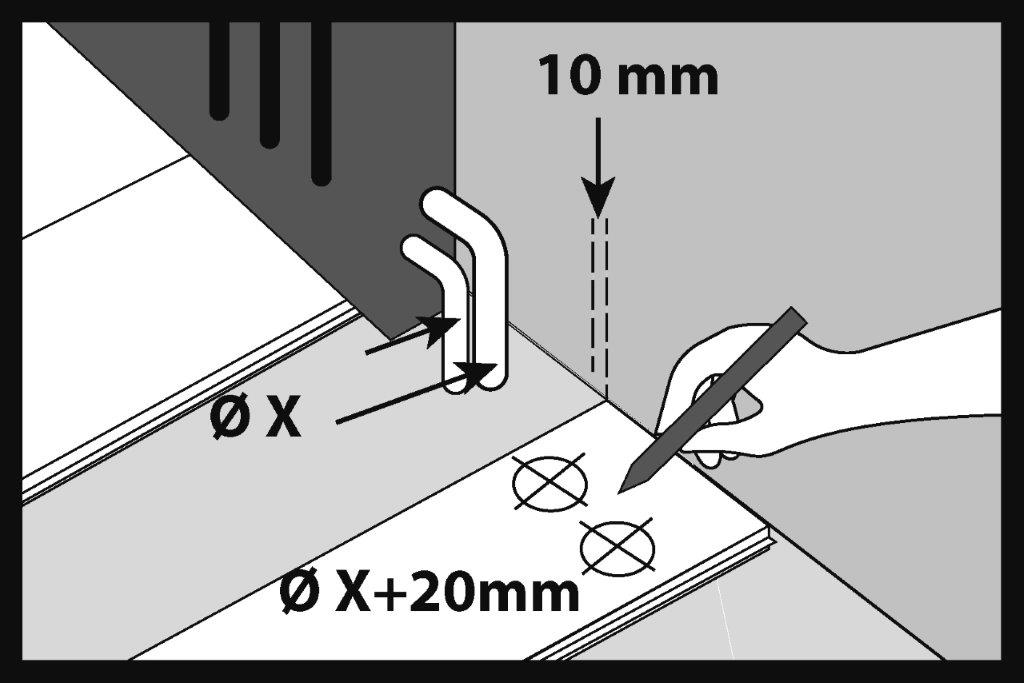

27.

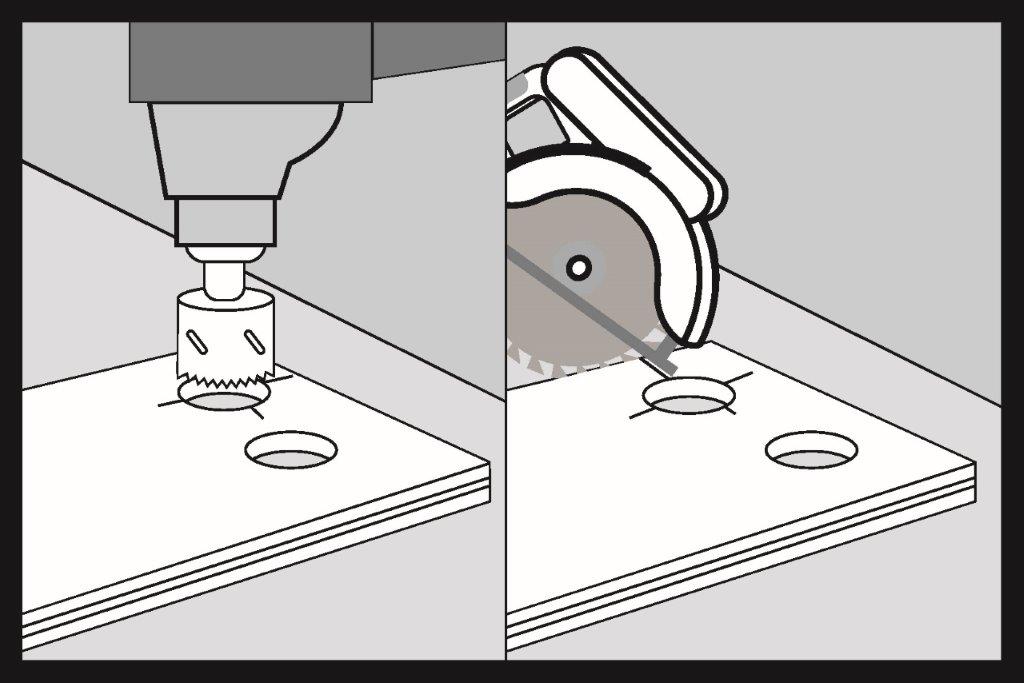

Draw holes for radiator pipes with a diameter larger by 20 mm than the diameter of the pipes on the SPC panel.

28.

Cut holes in the SPC panel. Draw a line through the centre of the holes and cut the panel with a circular saw.

29.

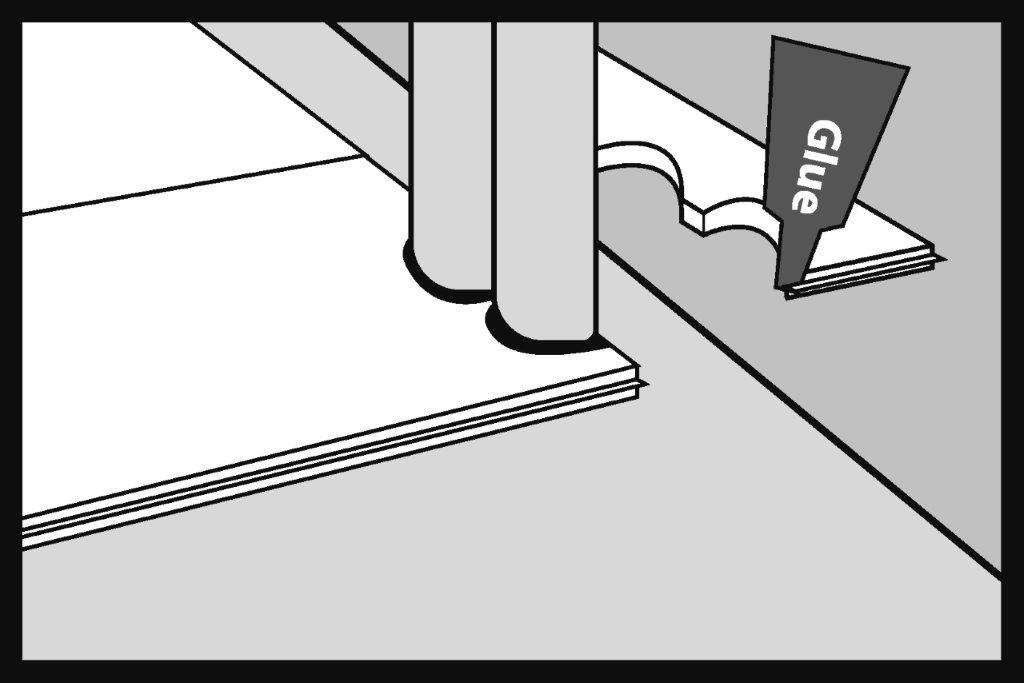

Glue the cut piece of the panel using assembly adhesive.

30.

Important: There is no need to make an expansion gap in the passages from one room to another. Only leave expansion gaps next to walls and other structures permanently embedded in the building, e.g. stairs, columns and other obstacles.

The maximum dimensions of the floor plan of a house/apartment for which the SPC floor installed as a floating floor does not require expansion gaps in doorways are 15×15 m.

31.

Knock home the final row of the SPC panels using a metal lug.

32.

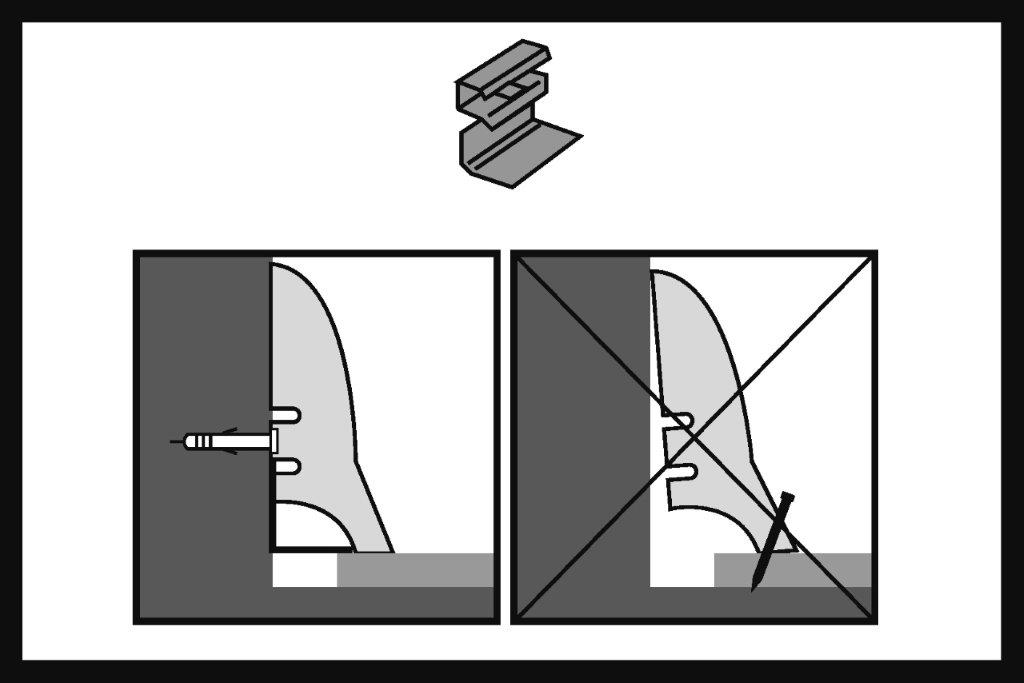

After installing the entire floor, install decorative skirting boards. Attach the skirting boards only to the walls using assembly clips or assembly adhesive.

33.

A natural floor layout can be achieved by mixing panels of different lengths in one row of panels. The minimum recommended shift of the joints on the short edges of the SPC panels in adjacent rows of panels must be greater than 200 mm.

Installation of the SPC panels using the adhesive installation system

34.

For adhesive installation of the floor, use the recommended adhesive system described at www.barlinek.com

Glue the SPC panels to the subfloor using dedicated adhesives. After installing several rows of panels, press the floor with heavy objects (e.g. packaging with unused panels).

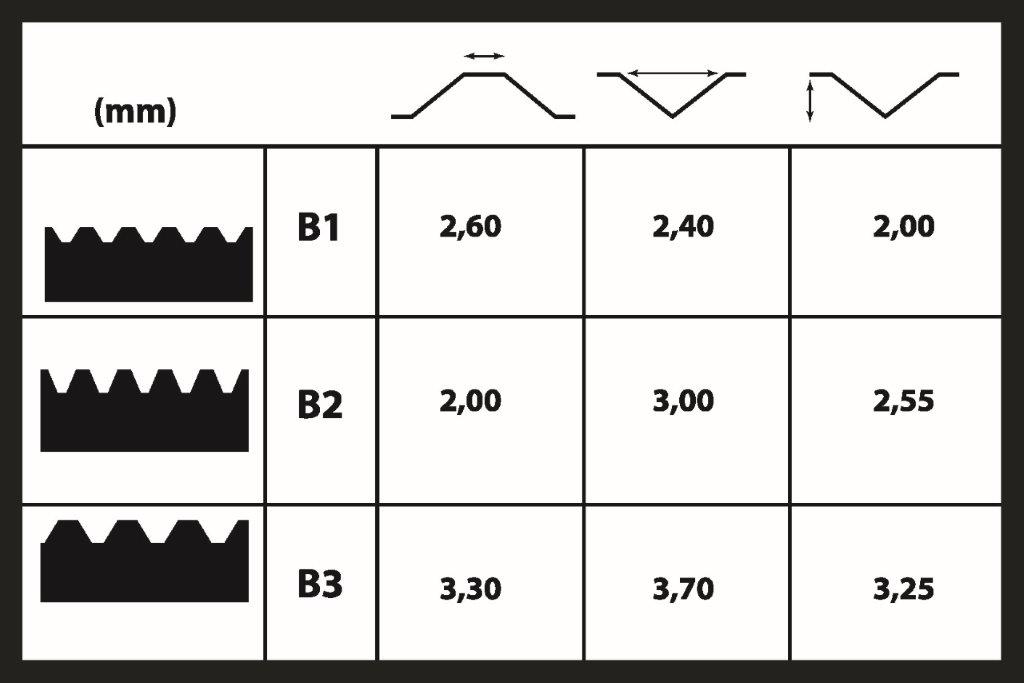

Depending on the selected adhesive system, use a B1, B2 or B3 trowel.

- SPC panels – gluing with recommended adhesives; for more information please visit www.barlinek.com

- Check the hardness of the screed with a surface hardness tester “Ri-Ri”; the spring tension in the lower position.

- Screeds must be sanded – anhydrite screeds must be sanded until the grains become visible.

- Priming must be used when gluing panels on anhydrite screeds.

- Self-levelling compounds – use CT type (cement) compounds with strength parameters of at least C25, F6.

Installation of the SPC panels on an underfloor heating system

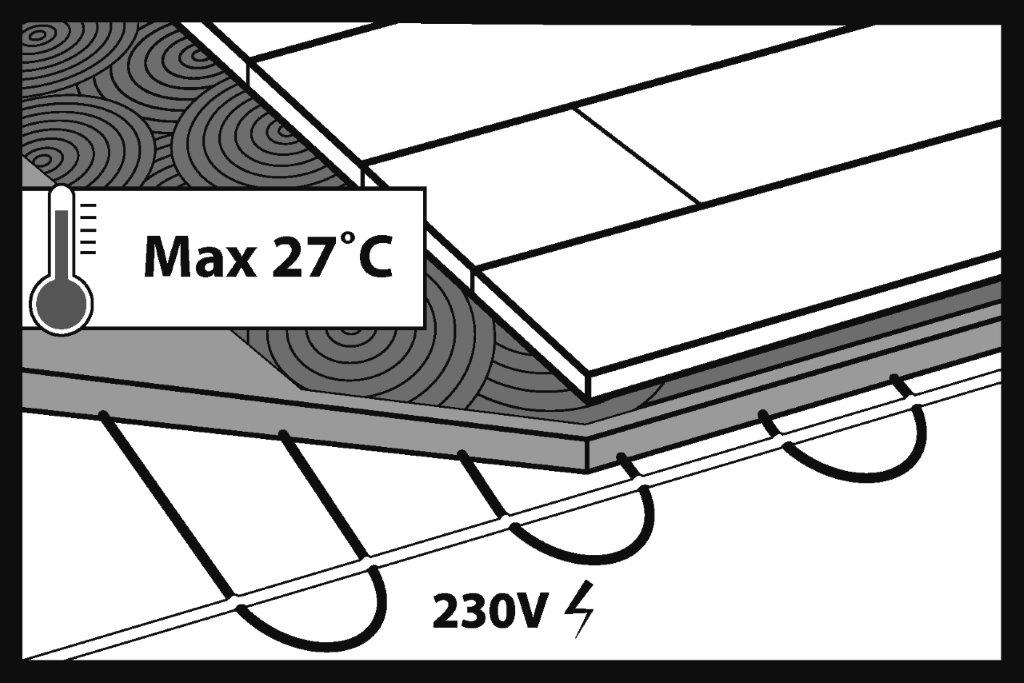

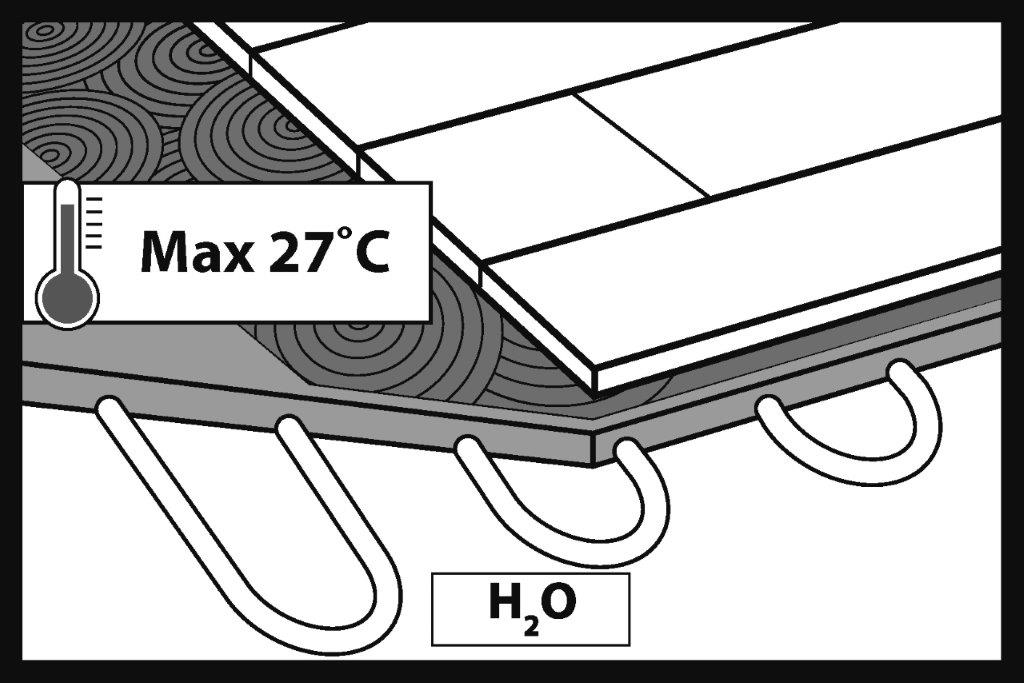

35.

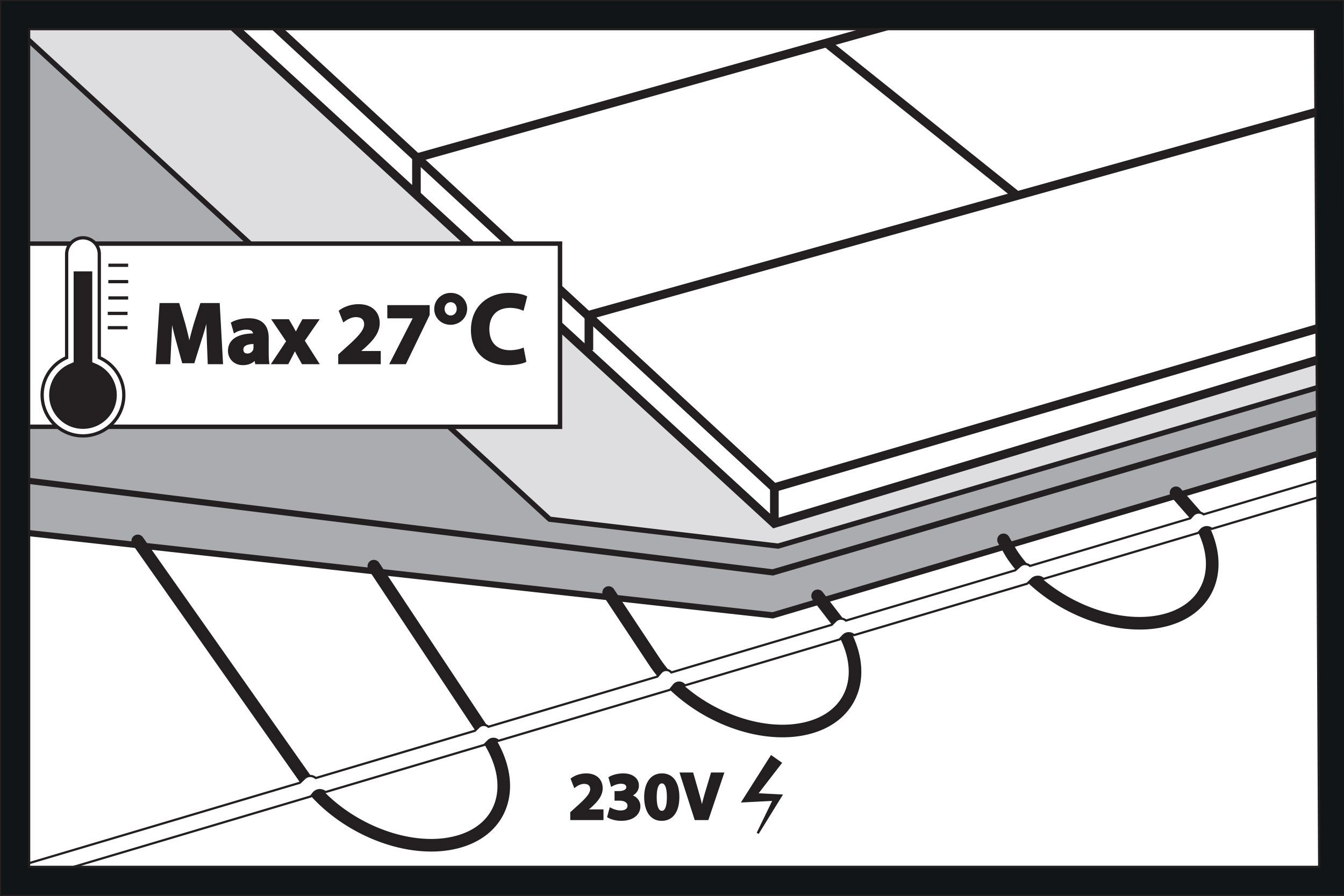

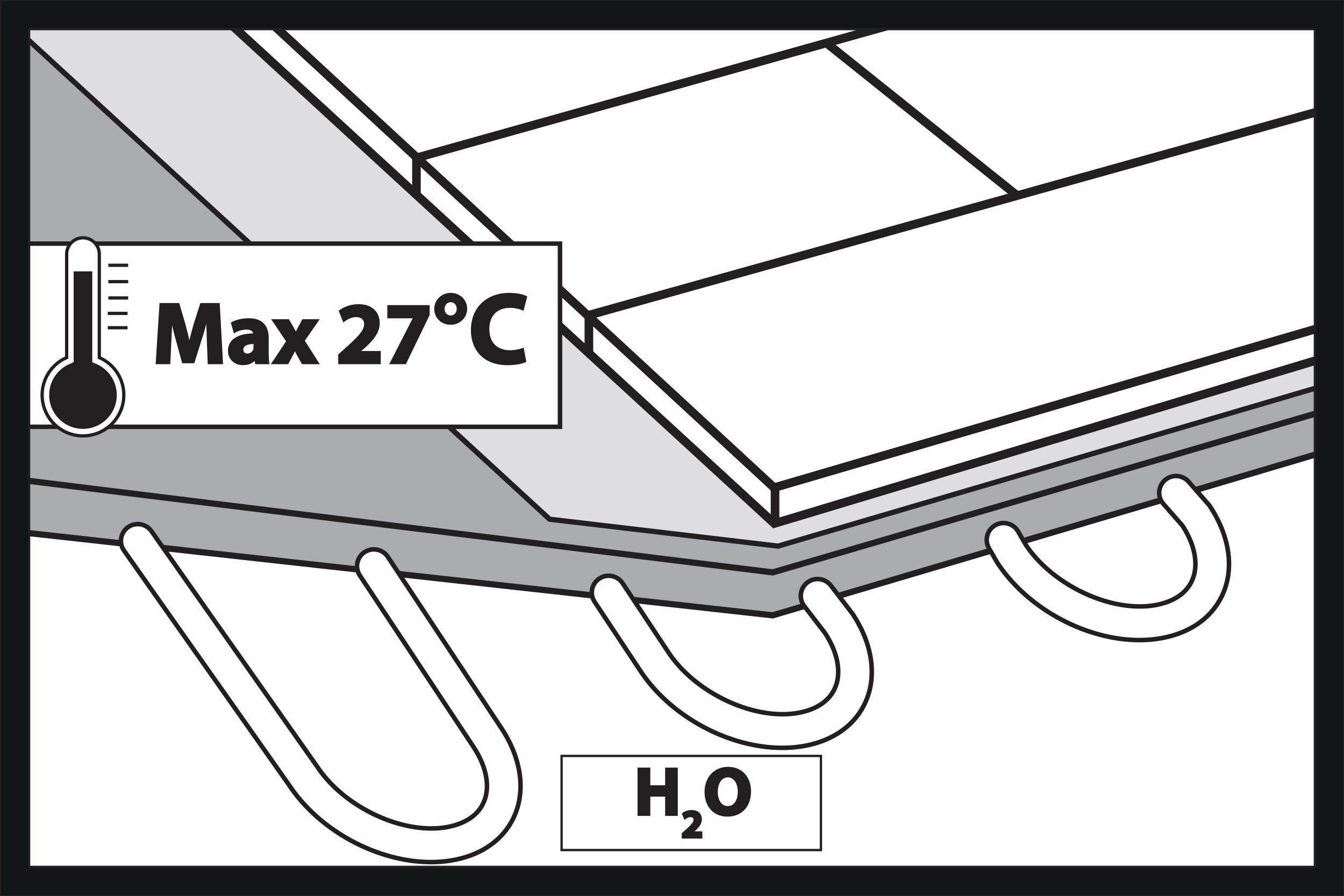

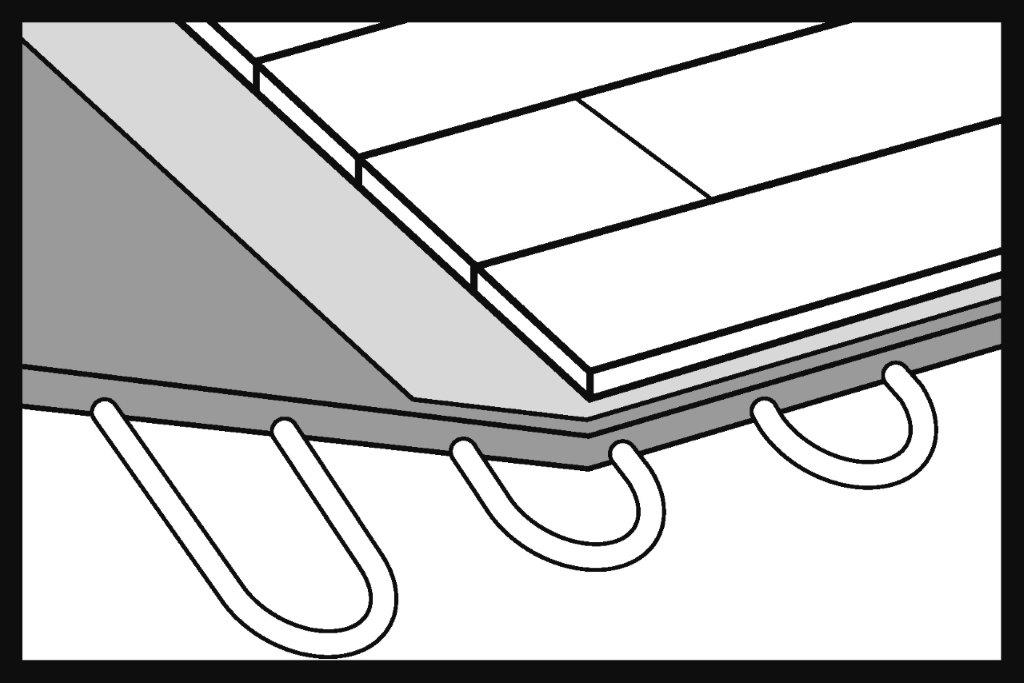

The SPC floors can be installed on a water or electric underfloor heating system. The floorboards can be glued to the screed or installed as a floating floor.

Important:

The precondition for laying the panels on an underfloor heating system is to conduct the screed heating process and prepare a screed heating report – this only applies to new, unheated screeds.

The information on the screed heating and the screed heating report are available at barlinek.com. The screed heating process should also be performed in the summer.

Glue the floor using the recommended adhesive system. For more information, please visit www.barlinek.com.

Important:

Only the SPC panels without integrated underlay can be installed using the adhesive installation system.

The limit above which the heating system should not be set is 27°C on the panel surface.

- The screed moisture content for installation on an underfloor heating system should not exceed: 1.5% CM for cement screeds, 0.3% CM for anhydrite screeds.

- To avoid uneven operation of the panel core, the entire floor surface should be heated. If there are two or more heating loops in one room, the set temperature difference between the loops must not exceed 5°C. This also guarantees the greatest comfort of use (no colder spots on the floor surface).

For the SPC floors installed using the adhesive installation system on heated substrates, maintain expansion gaps between the heated surfaces and the surfaces without the underfloor heating system. The underfloor heating system should be started no earlier than 48 hours after the completion of the SPC floor installation. When using the SPC floor installed on an underfloor heating system, remember that the evaporation of any liquids spilled on the floor surface may be accelerated. Therefore, any stains of liquids such as wine, urine, milk, etc., should be removed from the floor surface immediately, because if they dry on the SPC panel surface, they may cause permanent discolouration of the floor. The height of the screed overlay above the heating elements should be at least 20 mm.

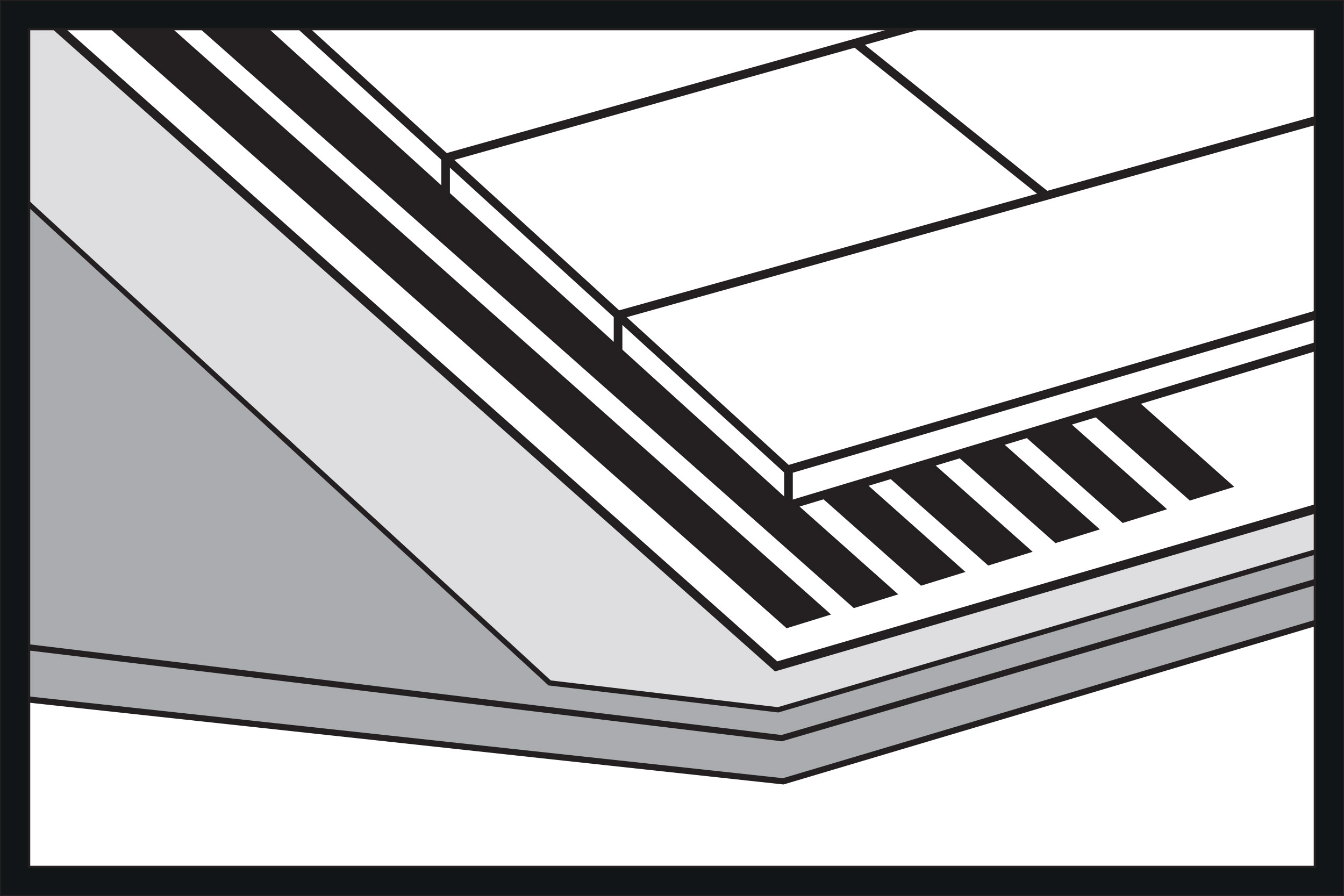

Installation on heating foils – infrared heating mats:

- underlay – minimum 4 mm thick, well insulating – usually XPS with CS≥400 kPa; the thickness of the underlay should allow for the placement of connectors and cables;

- heating foil;

- vapour barrier film or construction membrane;

- SPC floor

Controllers and floor temperature sensors must be used. For fitters – thermal seals are recommended.

Furniture placed on the floor with an underfloor heating system, e.g. sofas, should have legs at least 10 cm high.

Installation of the SPC panels on underfloor cooling systems

36.

It is very important that the underfloor cooling system is equipped with appropriate control systems that prevent water vapour condensation on the floor surface. To prevent this, the temperature of cold water in the underfloor cooling system pipes should not fall below a specified value. Each room with an underfloor cooling system should have a sensor installed that calculates the dependence of relative air humidity on the floor panel surface temperature and cuts off the cold water supply before the so-called dew point is reached, i.e. before water vapour begins to condense on the surface of the panels.

Thermostats in rooms should not be set to a temperature lower than 23°C. In addition, the difference between the temperature set on the thermostat and the room temperature should not exceed 5°C. Example: room temperature is 30°C, temperature set on the thermostat is minimum 25°C.

The underfloor cooling system should be protected against a drop in the water temperature in the system below +18°C.

The maximum thermal resistance of the installed floor is R≤0.15m2K/W. To ensure minimum thermal resistance, Barlinek recommends using an adhesive floor installation system or a floor underlay with a very low heat loss coefficient: i.e. the EXTREME 1.5 underlay offered by Barlinek.

- Switch off the underfloor cooling system 48 hours before installing the floor. The underfloor cooling system can be restarted 48 hours after the floor installation.

- The moisture content should not exceed 1.8% for cement screed and 0.3% for anhydrite screed. Measurements should be performed using the carbide method, the so-called CM method.

- Other installation and use parameters are in accordance with the installation instructions and the Terms of Use and Care of the SPC Floors. For more information, please visit barlinek.com

To decide whether to use an underfloor cooling system, a heat balance should be prepared at the design stage. Otherwise, the cooling equipment may be selected incorrectly and the entire cooling system may not operate efficiently enough.

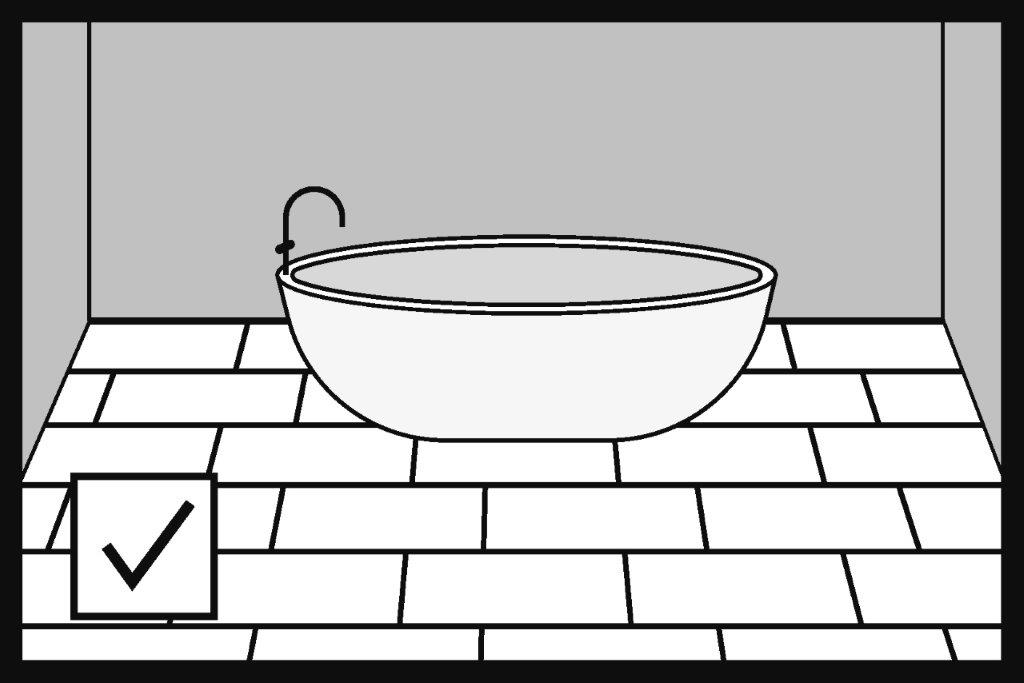

Installation of the SPC panels in wet rooms

37.

The SPC panels can be installed in bathrooms and other rooms where water spills may occur.

- In these types of rooms, we recommend using an adhesive installation system. In this case, the size of the perimeter expansion gap can be reduced to 3 mm. If the SPC panels are glued in other rooms, there is no need to leave an expansion gap in the door frame. If the SPC panels are installed as a floating floor in other rooms, it is necessary to leave an expansion gap with a width of at least 5 mm in the door frame (suitable for the type of masking expansion gap strip).

Glue the floor using the recommended adhesive system.

For more information, please visit www.barlinek.com.

- When installing the SPC panels as a floating floor in bathrooms, leave an expansion gap with a width of at least 5 mm in the door frame (suitable for the type of masking expansion gap strip). The expansion gap can be filled with an elastic filler). When installing the panels as a floating floor, always leave a perimeter expansion gap with a width of 5 mm. Regardless of the floor installation method used in other rooms, the bathroom floor should be separated from other rooms by an expansion gap.

- Regardless of the floor installation system (floating or adhesion installation system) used in bathrooms with an underfloor heating system, leave an expansion gap in the door frame to separate the bathroom from other rooms.

Leave expansion gaps around walls, shower tray casings, bathtubs, toilet bowls and other obstacles permanently attached to or embedded in the screed.

Important:

Do not install the SPC panels in shower trays, baths, saunas, swimming pools and similar places.

Care and use of the SPC panels

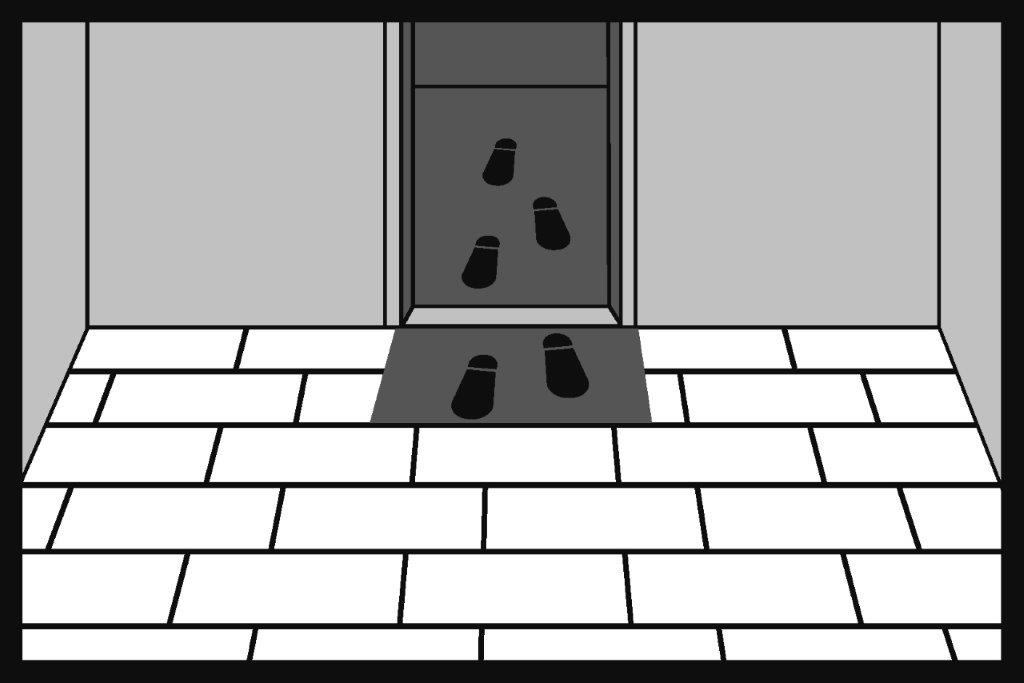

38.

Place doormats at the entrances to the apartment to effectively prevent sand, earth and water from being brought in on the shoe soles. Protect your floor by placing protective mats in front of and/or behind each entrance. Protective mats will collect dirt, sand, pebbles and other solid particles and absorb moisture. Keep protective mats clean. Do not use latex or rubber backed mats on the SPC floors as some compounds in latex and rubber can permanently stain or damage the panels. Protective mats for laying on the SPC panels should be marked as “non-staining”.

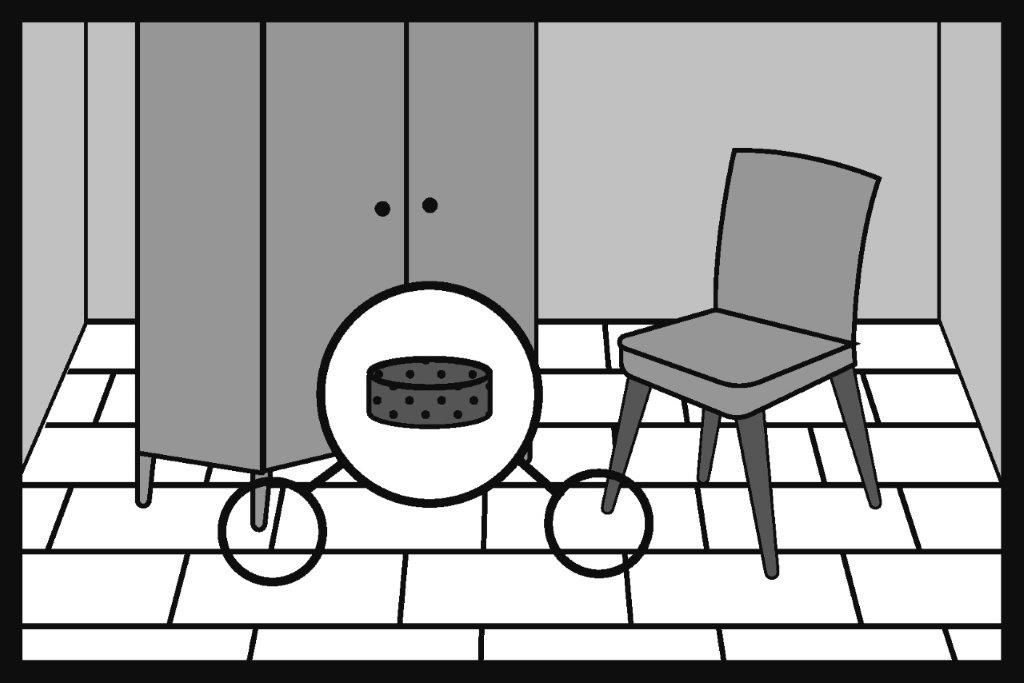

39.

All furniture and other devices that are in contact with the floor should be equipped with protective pads, e.g. felt pads, which should be replaced regularly.

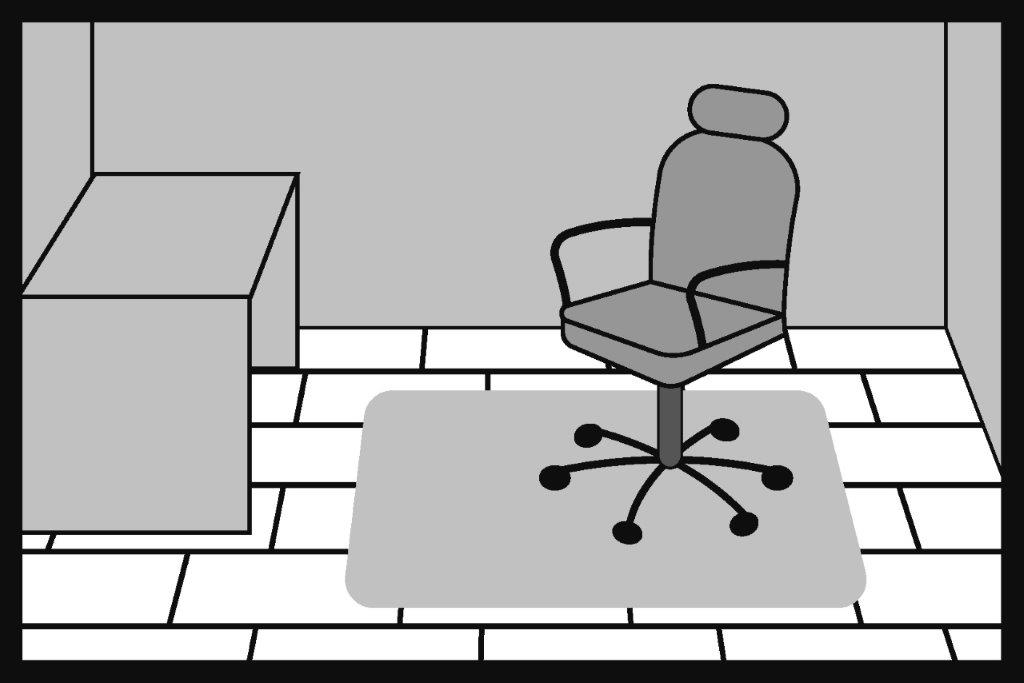

40.

Place armchairs and other furniture equipped with hard plastic casters on plastic protective mats. If the protective mats are not used, replace the castors with W-type hard floor castors.

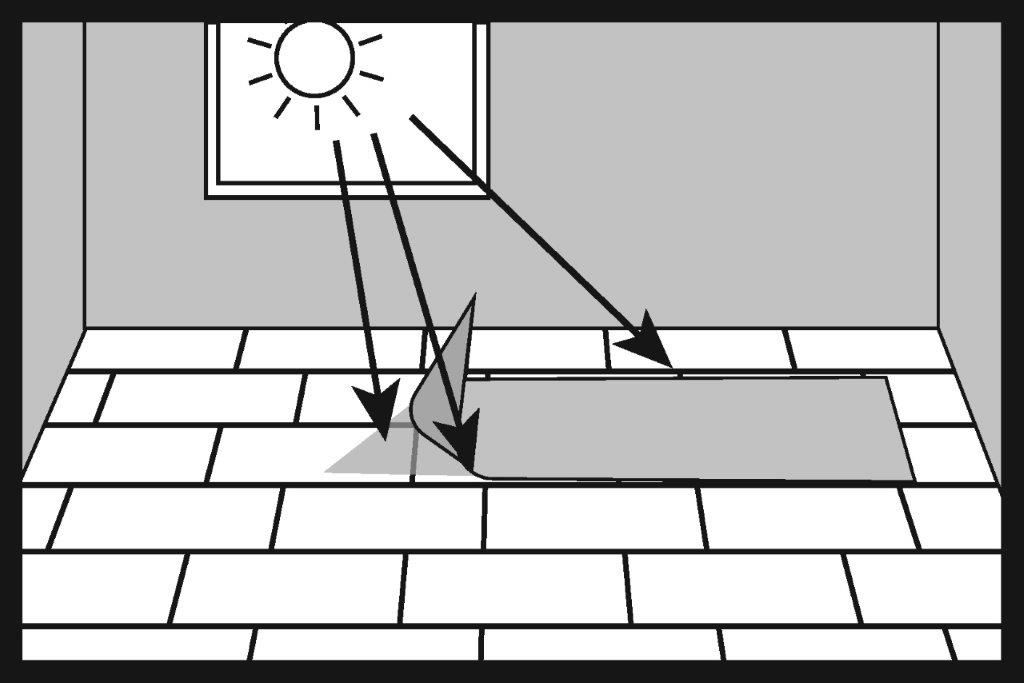

41.

The floor exposed to sunlight (UV light) will change its original colour.

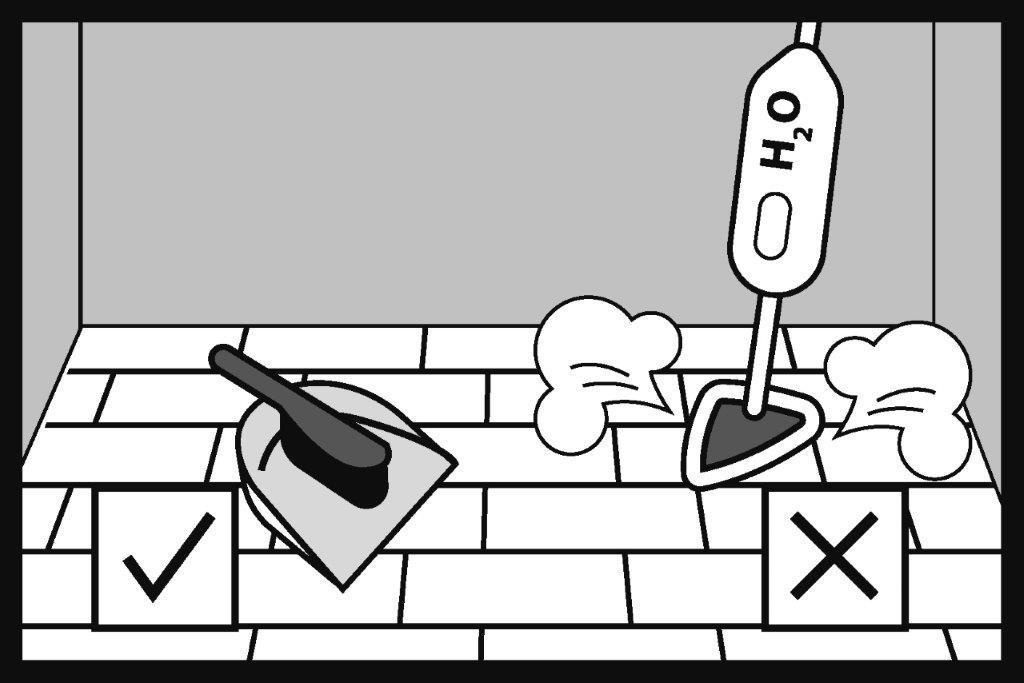

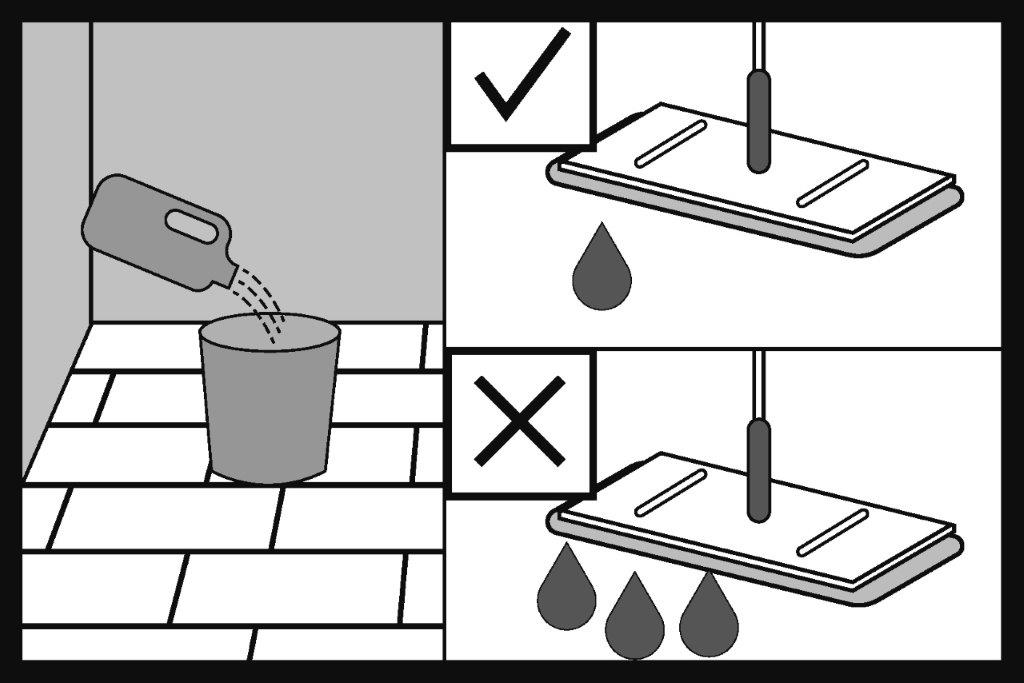

42.

The floor is factory finished and ready for use immediately after installation. Floor care should only be carried out using products designed for this purpose. The SPC floor care instructions can be found at barlinek.com

- Never use vacuum cleaners with a brush that can damage the floor.

- Immediately remove any water spills.

- Vacuum or sweep the floor to remove any particles that can scratch it.

- You can use a damp cloth with or without a recommended floor care product. Do not leave wet marks on the floor after cleaning.

- Do not use high-pressure or steam washers to clean the floor.

- Trim pets’ claws to prevent damage to the floor.

- Do not move heavy furniture or equipment across the floor.

- Floor care products other than those recommended by Barlinek may damage the varnish layer, change the colour and gloss of the floor and stain the floor.

- Do not use wax, paraffin or silicone-based floor care products.

- For daily care, we recommend dry cleaning (vacuuming, sweeping).

Clean the floor with a mop, along the panels.

43.

The temperature in the room where the floor is installed should be between +18°C and +29°C.

44.

Important

The Terms of Use and Care of the SPC Floors and the Warranty Conditions for the SPC Floors can be found at barlinek.com.